Choosing the right mulcher teeth for your forestry mulcher can feel overwhelming, especially with so many brands, designs, and specifications available. From tooth type and terrain conditions to vegetation density, machine compatibility, maintenance needs, and budget. There's a lot to think about.

(Image Source: xtremewearparts.com)

But don't worry! We've simplified the process for you. Now, we'll walk you through the key factors to consider when selecting the most suitable mulching teeth for your application, helping you make an informed decision that boosts efficiency and minimizes wear.

Types of Mulcher Teeth

Designed with different features and for different purposes, mulcher teeth mainly have two types:

Carbide Mulcher Teeth

(Image Source: xtremewearparts.com)

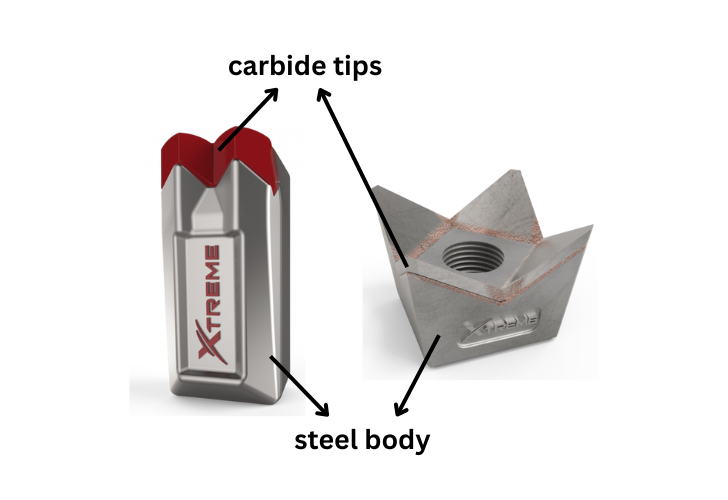

When it comes to tough land-clearing conditions, such as rocky ground, abrasive terrain, or heavy-duty vegetation, carbide mulcher teeth stand out as the preferred choice for many professionals. Designed with wear resistance and durability in mind, these teeth are commonly used in forestry mulchers for large-scale forestry mulching, right-of-way clearing, and commercial vegetation management.

Unlike standard steel or forged alternatives, carbide mulcher teeth are tipped with tough tungsten carbide, allowing them to endure repeated impacts from rocks, stumps, and debris without dulling quickly. These carbide mulching teeth require little to no sharpening and can last three to six times longer than traditional options, especially when properly rotated and maintained.

While carbide teeth for forestry mulchers may not offer the clean slicing of forged knives, they deliver unmatched reliability in high-impact environments. This makes them especially valuable on powerful mulching equipment where raw force is prioritized over fine finish. Whether you're reclaiming overgrown land, managing underbrush, or tackling challenging soil conditions, carbide-tipped mulcher teeth ensure fewer replacements, reduced downtime, and consistent cutting performance.

For professionals operating in unpredictable or abrasive field conditions, investing in high-quality carbide mulcher teeth is not just a smart decision; it's a long-term advantage in performance, productivity, and cost efficiency.

Steel Mulcher Teeth

(Image Source: xtremewearparts.com)

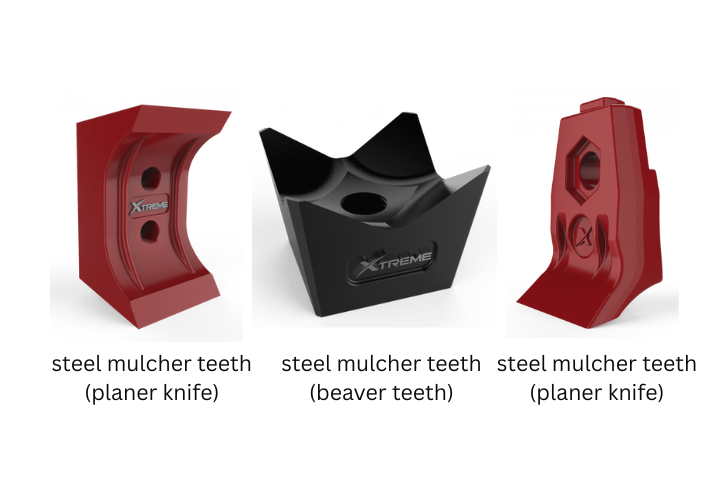

Steel mulcher teeth, or forged mulcher teeth, are a go-to choice for projects that demand sharp, fast, and efficient cutting, particularly in light-duty forestry mulching applications. These teeth are engineered for precision work, making them highly effective when clearing softwoods, brush, and thinner vegetation. Unlike carbide mulching teeth that rely on impact to break down material, steel mulcher teeth slice cleanly through wood, delivering finer mulch and a neater finish.

One of the standout features of steel mulcher teeth is their blade-like edge, which is similar to the action of a chainsaw or axe. This design reduces strain on the forestry mulcher, improves fuel efficiency, and leaves behind uniform wood chips—ideal for landscaping or aesthetic site clearing. Forged mulcher teeth are particularly well-suited for operators seeking speed and visual quality over brute-force grinding.

While they are more affordable than carbide alternatives, forged steel teeth require more maintenance. Regular sharpening is necessary to keep the cutting edge in top condition. Sharpening can be done with an angle grinder, ideally after removing the teeth from the disc for safety. For safety concerns, professional sharpening services are highly recommended. Over time, even with maintenance, the steel will wear down and eventually require replacement.

If your land clearing priorities include clean cuts, faster processing of light vegetation, and a polished final result, forged mulcher teeth offer a reliable, cost-effective solution, especially for forestry mulcher operators working in controlled or less abrasive conditions.

Terrain and Vegetation Types

Selecting the right mulcher teeth depends heavily on the terrain and vegetation you're working with. For forestry mulching projects in rocky or abrasive conditions, carbide mulcher teeth are the preferred choice. Their superior durability and resistance to impact make them ideal for challenging environments where steel would wear out quickly.

In contrast, if you're operating in softer soil or clearing light brush, steel mulcher teeth can be a cost-effective alternative. These forged knives offer cleaner cuts and faster processing, especially when appearance and mulch consistency are priorities.

For dense vegetation or thicker tree trunks, heavy-duty forestry mulcher setups benefit from reinforced cutting edges—either robust forged teeth or specialized carbide options designed for high-impact applications.

When working across mixed terrain, many operators opt for a combination of carbide teeth on the outer edges (for durability) and steel or forged knives in the center (for performance). This setup balances efficiency and longevity, but proper tooth distribution is essential to maintain rotor balance and reduce vibration.

By matching your mulching teeth to the jobsite conditions, you not only extend equipment life but also improve productivity and mulch quality.

Mulcher Teeth Maintenance

Keeping your mulcher teeth in good condition is essential for ensuring consistent cutting performance and extending the lifespan of your forestry mulcher. Whether you're using carbide mulcher teeth or steel mulcher teeth, routine care plays a crucial role in avoiding unnecessary downtime and equipment wear.

Installation matters. Make sure each tooth is installed tightly and torqued according to the manufacturer's specifications. Loose or improperly fitted teeth can lead to uneven wear, vibration, and reduced mulching efficiency. If your machine supports it, rotating the teeth periodically can help promote even wear across the cutting surface.

Regular inspection is key. Check your forestry mulcher teeth before and after the operation. Replace dull or damaged teeth promptly; running a mulcher with worn teeth can increase fuel consumption, strain the machine, and reduce overall productivity. For forged steel teeth, sharpening is necessary to maintain clean, fast cuts. In contrast, carbide teeth are low-maintenance but should be replaced once carbide tips wear down.

To prevent buildup that may reduce cutting performance, clean the mulcher head after each use. And whenever possible, avoid excessive contact with rocks and hard surfaces, especially when using non-carbide tools.

Investing in high-quality replacement teeth from trusted suppliers helps ensure durability and performance. With proper maintenance, your mulcher will run more efficiently, reduce operating costs, and stay job-ready in the long run.

Popular Forestry Mulcher and Mulcher Teeth Brands

When selecting mulcher teeth, it's also important to consider the compatibility with your forestry mulcher. Here are some well-known brands in the market:

(Image Source: The official sites of the following brands.)

Forestry Mulcher Brands

FAE – Known for powerful, high-performance mulching attachments.

Fecon – Offers a wide range of mulchers for skid steers, excavators, and tractors.

Prinoth – Specializes in advanced, heavy-duty mulchers for forestry and land management.

Gyro-Trac – Recognized for its lightweight yet powerful mulchers.

Rayco – A reliable choice for vegetation management and right-of-way clearing.

Tigercat – Offers robust machines for demanding forestry applications.

Mulcher Teeth Brands

Quadco – Known for high-quality carbide teeth and saw teeth systems.

Loftness – Offers durable teeth systems for various mulching heads.

Seppi M. – Supplies forestry mulching heads and wear parts across multiple applications.

Fecon – Also provides their own line of mulcher teeth compatible with Fecon heads.

Remember: Always check the specifications of both your mulching head and replacement teeth to ensure proper fit and performance.

*All of the above images are not intended for commercial use.