In the world of land clearing, choosing the right forestry mulcher can make all the difference. A mulching head, typically mounted on a skid steer, excavator, or tractor, is designed to cut, grind, and shred overgrown vegetation, leaving a nutrient-rich layer of mulch behind. Among the most common types are the drum mulcher and the disc mulcher, each with its own strengths and limitations.

(Image Source: bobcat.com)

So, as for drum mulcher vs disc mulcher, which one is better for your land clearing project? Now, let's break down the features, advantages, and drawbacks of both types of mulching heads, helping you make the best decision based on your terrain, vegetation, and performance needs.

Drum Mulcher Features

(Image Source: bobcat.com)

Drum mulchers feature a cylindrical mulching head that closely resembles a drum, powered by a hydraulic piston motor. Due to their size and weight, they require high-flow hydraulics for optimal performance. Typically equipped with 20 to 50 mulching teeth, made from either carbide or steel, the drum rotates at high speed to shred unwanted vegetation into fine mulch. Cutting widths generally range from 50 to 72 inches, while the drum diameters are commonly between 12 and 24 inches.

Many professionals prefer drum mulchers for their ability to deliver a finer, more consistent finish than disc mulchers. They excel at producing high-quality mulch and are capable of grinding stumps and roots below ground level, something disc mulchers cannot do. Their wide cutting head allows them to handle large volumes of brush and trees efficiently.

Safety is another strong advantage. Operators have a clear view of the mulching head during operation, and since the debris is contained more effectively, the risk of being struck by flying material is significantly reduced, unlike disc mulchers.

However, the cleaner finish comes at a cost: faster tooth wear. It's important to inspect the mulching teeth after each job and replace any damaged or worn teeth promptly to maintain cutting performance.

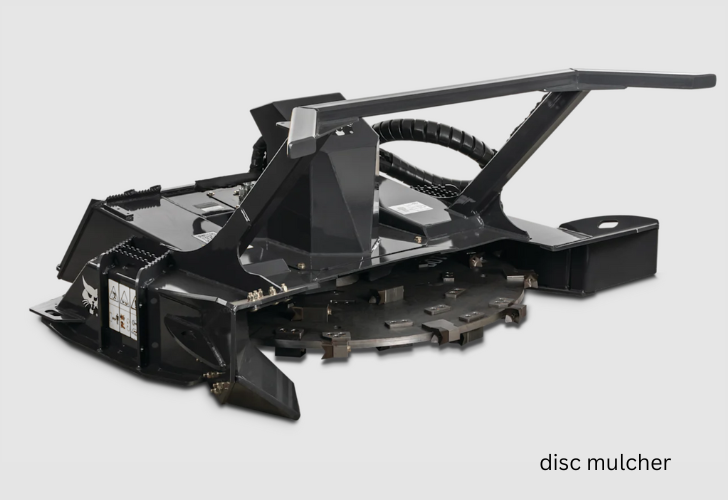

Disc Mulcher Features

(Image Source: bobcat.com)

Disc mulchers are powerful land clearing attachments designed for speed and efficiency. They feature a large, horizontally spinning disc—often called a blade carrier or flywheel—fitted with hardened steel or carbide-tipped mulcher teeth positioned along the top, bottom, and outer edge. When engaged, the disc spins at high speed, storing kinetic energy that allows it to shred through thick vegetation, trees, and brush in seconds.

These machines are especially effective for aggressive forestry mulching tasks, thanks to their wide cutting decks (typically 60 to 72 inches) and high-throughput design. Some models even feature twin discs powered by dual hydraulic motors, boosting both flow requirements and cutting performance.

Disc mulchers stand out for their ability to quickly clear land and process large volumes of material, though they generally leave behind coarser mulch and a rougher finish compared to drum mulchers. They are best suited for projects where speed is more critical than producing finely shredded mulch.

Additional features include:

- Lightweight build, which reduces strain on the carrier machine and keeps the center of gravity low.

- Standard flow compatibility, making them accessible for a broader range of skid steers and excavators.

- Lower maintenance needs, leading to less downtime and fewer servicing intervals.

While disc mulchers may not be the best option for below-ground stump grinding or producing uniform mulch, they’re an excellent solution for rapid land clearing and vegetation management, particularly in environments that demand high productivity and cost efficiency.

Drum Mulcher vs. Disc Mulcher: Cost

Drum mulchers are generally more expensive than disc mulchers. A typical drum mulcher can range from $30,000 to $50,000, depending on size and features like cutting widths, carbide teeth, pressure gauges, or hydraulic doors. In contrast, a disc mulcher is often priced between $20,000 and $37,000, making it a more budget-friendly option for many land clearing projects.

While drum mulchers involve a higher upfront investment, they also include more moving parts and complex systems, which may increase long-term maintenance costs. However, drum mulcher teeth are usually fewer in number and easier to replace than those on disc models.

Drum Mulcher vs. Disc Mulcher: Finish

Drum mulchers are known for delivering a finer, more uniform mulch, making them a better choice if you're aiming for a clean, polished result, or if you plan to resell mulch. Their precision cutting creates shredded wood chips that often require little to no follow-up work.

Disc mulchers, on the other hand, prioritize speed and aggressive cutting power. While they process material quickly, they tend to leave behind larger wood chunks that may require additional cleanup, or reprocessing to achieve a neater finish. A disc mulcher can eventually produce more refined mulch with multiple passes, reducing overall efficiency.

If appearance and mulch quality are important for your forestry mulching project, a drum mulcher may be a better investment.

Drum Mulcher vs. Disc Mulcher: Speed & Productivity

Productivity is a critical factor for clearing land efficiently and the performance of a forestry mulcher can vary significantly depending on its design. Disc mulchers are widely recognized for their speed. Thanks to their high-momentum flywheel and relatively lighter build, they can quickly cut through dense brush and small to medium-sized trees, often shredding entire trees within seconds. Under favorable conditions, experienced operators may clear 1.25 to 1.5 acres per day using a disc mulcher.

Drum mulchers, by contrast, tend to offer more precision than speed. Their productivity is influenced by factors like vegetation density, terrain, soil moisture, and the mulching strategy, whether you're spot-mulching or performing a full clear. While slower than disc models, drum mulchers are consistent performers and are especially effective when a fine finish is required. In typical conditions, a drum mulcher may clear around 1 acre per 8–10 hour day.

In short, if speed and aggressive material reduction are your top priorities, a disc mulcher may provide a better return on time.

Drum Mulcher vs. Disc Mulcher: Stump & Root Grinding

(Image Source: unsplash.com)

Speaking of stump & root grinding, drum mulchers offer a clear performance edge over disc mulchers. Thanks to their open, cylindrical design, drum mulchers can grind stumps up to 2 inches below ground level, effectively removing both the stump and parts of the root system. This deeper cut not only eliminates regrowth but also helps loosen and expose topsoil, making replanting or site restoration easier.

By contrast, disc mulchers are generally limited to grinding stumps at or just slightly below grade. Their cutting disc is set at an angle to minimize contact with soil, helping protect the cutting teeth from dulling too quickly. While this design improves tooth longevity, it also limits the machine’s ability to handle extensive root systems or deeply embedded stumps.

For projects where complete vegetation removal and soil preparation are priorities, a drum mulcher is often the better long-term investment.

Drum Mulcher vs. Disc Mulcher: Safety Considerations

Safety is a key concern when operating forestry mulchers, especially in urban areas or active job sites. One of the main differences between drum mulchers and disc mulchers lies in how they handle debris. Drum mulchers produce finer mulch and discharge it more downward and in a controlled manner, making them a safer choice for residential zones or areas with bystanders. In contrast, disc mulchers can eject large wood chunks unpredictably and at greater distances, posing a higher risk in populated environments.

To protect both the operator and equipment, most manufacturers recommend using shatterproof polycarbonate cabs, falling object protection systems (FOPS), and protective components like motor guards and pressure relief valves. Regardless of the machine type, maintaining a 300-foot safety radius around the work zone is advised to reduce the risk of injury from flying debris.

If your project involves tight spaces, urban settings, or public areas, a drum mulcher offers a more controlled and safer mulching process.

Drum Mulcher vs. Disc Mulcher: Operation

Of the two mulcher types, drum mulchers are generally easier to operate because of their excellent maneuverability and visibility, making them more suitable for both experienced and new operators. Some models also feature pressure gauges, helping novice users load the hydraulic system properly.

In contrast, disc mulchers demand a higher level of skill and experience, particularly when it comes to guiding trees accurately into the cutting zone for efficient processing. While both tools require professional handling, drum mulchers are typically more user-friendly in daily operation.

Drum Mulcher vs. Disc Mulcher: Motor

Drum mulchers typically rely on bent-axis piston motors, which are known for their strong torque and efficient performance. There are two main motor options: fixed displacement and variable displacement. A fixed displacement motor operates at one speed with maximum torque, simple and affordable, but limited in adaptability. On the other hand, variable displacement motors automatically adjust between high torque and high speed based on the vegetation density. This makes them ideal for maximizing productivity and reducing the risk of stalling, especially in tough conditions.

Disc mulchers, in contrast, may come with gear motors as a lower-cost alternative, but this choice compromises cutting efficiency. The preferred choice remains a bent-axis piston motor (fixed displacement), offering strong torque, quick recovery, and better thermal management for the hydraulic system.

Drum Mulcher vs. Disc Mulcher: Mulcher Teeth

(Image Source: bobcat.com)

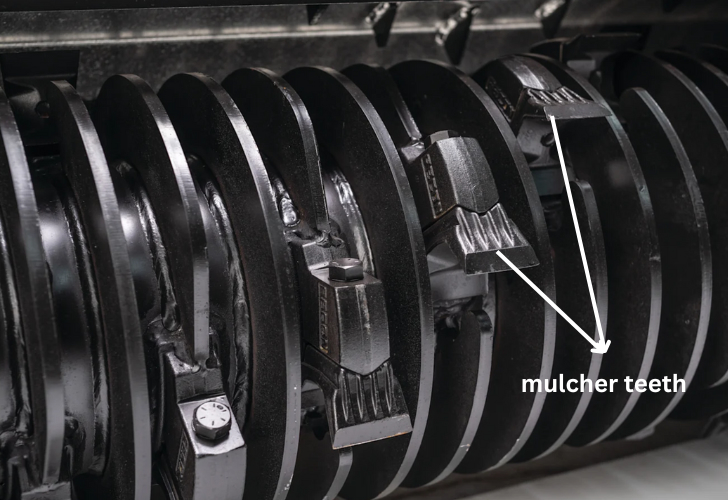

When selecting mulcher teeth for your forestry mulcher, it's important to consider not just the tooth material, but also the drum design or disc configuration.

Generally, there are two types of drums: smooth drums and bite control drums. Although more expensive, bite control drums limit how much material the drum engages at once, resulting in smoother operation, more uniform mulch, and fewer stalls, making them especially suitable for processing thick vegetation or for operators new to forestry mulching. Smooth drums may throw larger pieces around and pull the machine into stumps, increasing the risk of stalling.

Carbide mulcher teeth are widely used on smooth drums due to their durability in rocky or abrasive terrain. However, for bite control drums, steel mulcher teeth (especially forged planer knives) often perform better, delivering cleaner cuts and faster processing. Many experienced operators combine both types, placing steel teeth in the center of the drum, where most mulching occurs, and carbide teeth on the outer edges to handle impact from rocks and minimize wear. This hybrid approach balances efficiency and longevity while maintaining rotor balance.

In contrast, disc mulchers operate best with a fully machined, precisely balanced disc featuring bolt-on tooth mounts and replaceable bolt-on teeth. This design simplifies maintenance, allowing for quick tooth rotation or replacement without the need for welding, crucial for minimizing downtime during high-demand operations.

(For more information about mulcher teeth → Choosing Mulcher Teeth: Steel vs. Carbide and What Works Best )

Drum Mulcher vs. Disc Mulcher: Maintenance

Drum mulchers typically demand more time, cost, and mechanical expertise than disc mulchers, mainly due to their more complex design and greater number of moving parts.

Drum mulchers are built with additional components such as wear liners, drum bearings, timing belts, sheaves, and drive belts, all of which require regular inspection and servicing.

Another key aspect of drum mulcher upkeep is dynamic balancing. Even a small imbalance can cause significant vibration that renders the mulcher difficult or even unsafe to operate. Rebalancing a drum requires specialized equipment or third-party service, making it more complex than maintaining a disc mulcher. Additionally, most drum models are powered through a drive belt system, which should be visually inspected weekly and lubricated every 40 hours. Though belts are durable, replacing one can take up to two hours and requires moderate mechanical skill.

However, disc mulchers feature a simpler and more direct hydraulic drive with fewer moving parts. Most upkeep focuses on tooth replacement, which is straightforward thanks to bolt-on holders and pre-assembled tooth kits. Some disc mulchers do use an oil-filled gearbox, which should be inspected and topped off according to manufacturer guidelines. Accessing the oil reservoir may require detaching the hydraulic motor, adding some complexity depending on the model.

Drum Mulcher Vs. Disc Mulcher: Which One Is Right for You?

After comparing cutting performance, mulch quality, speed, safety, maintenance, and cost, the final question remains: which forestry mulcher type best fits your needs?

If your work involves clearing large trees quickly, especially in open or rural areas, a disc mulcher may be your best bet. It offers aggressive cutting power, faster processing speeds, and lower hydraulic demands, making it ideal for equipment without high-flow systems. However, keep in mind that it tends to produce larger mulch and scatter debris, so it's less suited for sensitive or residential sites.

On the other hand, if you're working near urban environments, roadsides, lakes, or power lines, or need precise control and a cleaner finish, the drum mulcher stands out. It produces finer mulch, grinds stumps below ground level, and directs debris safely downward, minimizing cleanup and environmental impact. It’s also a safer and more controlled choice in populated or sensitive areas.

In conclusion, the best choice depends on your typical job site conditions, equipment setup, and priorities, whether it's speed, mulch quality, operator safety, or terrain compatibility. By understanding the strengths of each mulcher type, you'll be better positioned to make a confident, cost-effective investment that delivers long-term performance.

*All of the above images are not intended for commercial use.