Road milling teeth, also known as road milling picks, road milling bits, or cold planer teeth, are the real workhorses behind every milling machine. They're the parts that actually make contact with the road, cutting and breaking the surface, so the milling drum can do its job. In other words, the performance of your cold milling machine largely depends on the quality and condition of its milling teeth.

(Image Source: wirtgen-group.com)

Now, I'll walk you through everything you need to know about road milling teeth. Here is what you'll discover:

- How many parts make up a road milling tooth?

- Where and how are road milling teeth used?

- Why do milling teeth matter so much?

- The different types of milling teeth

- Maintenance tips for longer service life

- How to select the right teeth for your milling machine

- Trusted brands worth considering

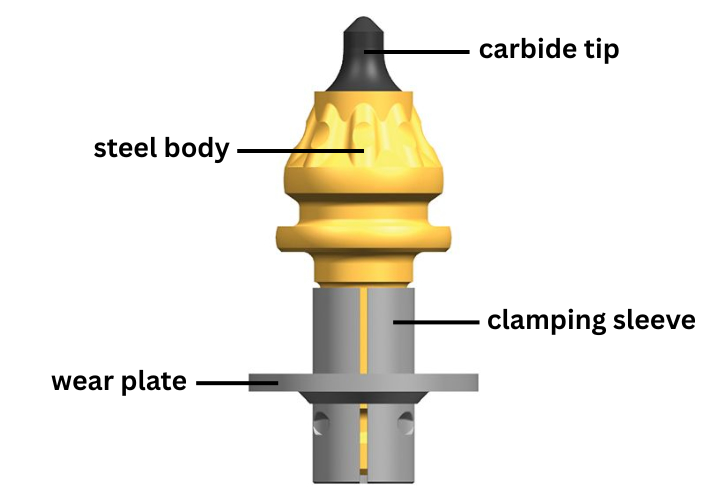

Components of A Road Milling Pick

Road milling teeth are made up of four key parts: a carbide tip, a steel body, a wear plate, and a clamping sleeve. Each plays a critical role in cutting performance and tool durability.

(Image Source: cat.com)

1. Carbide Tip

At the very top sits the tungsten carbide tip, the part that makes direct contact with asphalt or concrete. Known for its extreme hardness and wear resistance, the tungsten carbide material ensures efficient cutting and increases the overall service life of the tooth. This makes it suitable for milling everything from soft asphalt to tough concrete surfaces.

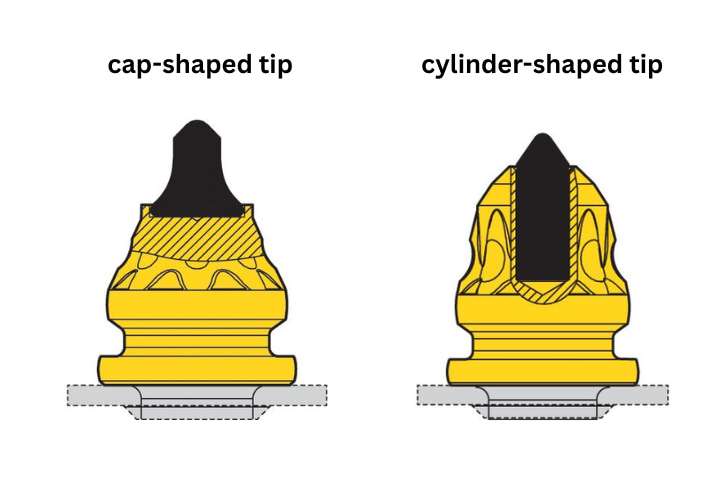

(Image Source: cat.com)

There are mainly two types of carbide tips: cap-shaped and cylinder-shaped. Cap-shaped teeth are designed to cut asphalt, while cylinder-shaped picks are used in concrete milling.

2. Steel Body

The tip is brazed onto the steel body, usually 42CrMo steel, which is designed to provide strength and stability. A well-built steel body not only supports the carbide tip but also helps with effective chip removal, further extending the pick's working life.

3. Wear Plate

The wear plate features grooves that allow the tooth to stay properly centered and rotate smoothly during milling. This design also reduces wear on the tool holder, protecting the machine and improving efficiency over time.

4. Clamping Sleeve

Finally, the clamping sleeve ensures the conical pick is securely fastened in the holder. A tight, stable fit means less vibration, better performance, and safer operation on the job site.

Applications of Road Milling Teeth

Their main job is simple yet critical: removing old and damaged pavement material with precision. Built with high-strength steel bodies and tungsten carbide tips, these cutting tools are tough enough to withstand the harsh conditions of milling asphalt and concrete.

In practice, milling teeth are applied in a wide range of projects, including road rehabilitation, pavement recycling, surface smoothing, and more. Whether the goal is full-depth removal or a shallow surface correction, road milling teeth ensure accurate material removal, improved surface quality, and safer roads.

Why Do Milling Teeth Matter So Much?

The choice of milling teeth can make or break your project. These small components determine how efficiently the machine cuts, how long the equipment lasts, and how much the whole operation costs. The right cold planer teeth deliver clear benefits:

- Excellent milling performance.

- Reducing replacement frequency and downtime.

- Reducing energy use and project expenses.

Types of Road Milling Bits

Not all milling jobs are the same, and neither are milling teeth. Different materials and project conditions require different types of cutting tools. Here are the main types on the market:

1. Carbide-Tipped Teeth

These are the most commonly used in standard milling. Equipped with tungsten carbide inserts, they offer excellent hardness and wear resistance. As I mentioned earlier, carbide teeth are durable enough to handle asphalt and even concrete, making them the reliable choice for most road milling projects.

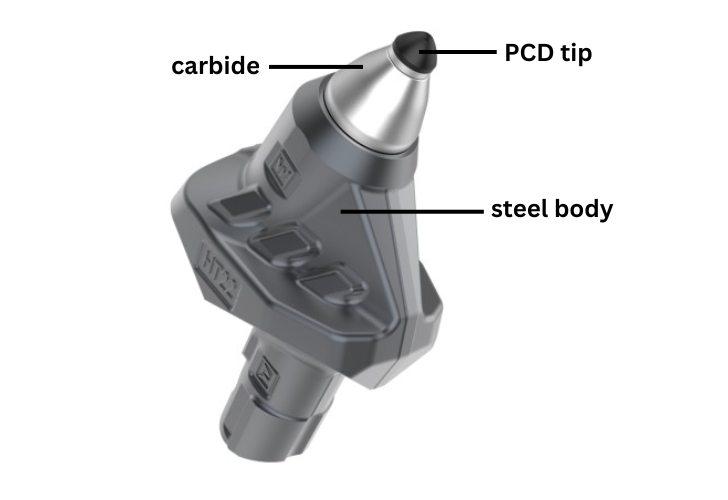

2. Diamond-Tipped Teeth

(Image Source: wirtgen-group.com)

When the job involves heavily reinforced concrete or extremely tough, abrasive materials, diamond-tipped teeth step in. PCD (polycrystalline diamond) is one of the hardest and most wear-resistant cutting materials available. PCD milling picks are designed for exceptional precision and efficiency in road surface rehabilitation.

What makes them unique is the tool tip: a polycrystalline diamond (PCD) tip welded onto the very end of a carbide tip. This smart combination brings together the solid strength of carbide and the extreme wear resistance of PCD. Compared to conventional carbide picks, PCD milling picks may be more expensive, but their long tool life and superior performance make them a cost-effective choice in the long run.

Maintenance Tips for Road Milling Teeth

With the right care, you can extend their service life , reduce replacement costs, and keep your milling projects running smoothly. Here are some key tips to keep in mind:

- When milling teeth hit obstacles like rocks, the carbide tips can chip or fracture. Always survey the site and avoid unnecessary contact with hard objects.

- Milling generates extreme heat. If the teeth overheat, wear accelerates dramatically. That's why the water spray system is critical. Make sure drains are clear and water flow is steady to keep the teeth cool and rotating freely.

- Running too fast increases tooth consumption and compromises surface quality. For long-term efficiency, both the drum and the machine should stick with recommended speeds whenever possible.

- Regular cleaning of the tool holders helps prevent sediment buildup. A clean holder ensures the teeth sit firmly and rotate as designed.

- Worn-out picks cut poorly, increase fuel consumption, and can damage the drum. Make inspections part of your routine, and replace teeth immediately once they're fully worn.

How to Select the Right Road Milling Teeth?

Selecting the right road milling teeth is about matching the teeth to your job, your machine, and your budget. Here's a breakdown of what to look for:

1. Understand Your Material

Start with the obvious: what are you cutting? Asphalt or concrete?

Asphalt: cap-style tips are suitable.

Concrete: cylindrical teeth work best.

For harder surfaces, go with tougher, thicker teeth that can handle high impact. For softer pavements, sharper and more economical teeth will cut faster and cost less.

2. Match Teeth to Your Machine

Road milling teeth basically come in two sizes: Φ20mm and Φ22mm, which are classified by the shank diameter. This makes it easier for operators to replace the picks. Besides, the size and power of the machine matter.

Smaller machines: shallower cuts, smaller tips, better cutting efficiency.

Larger machines: can take on deeper milling, but need thicker, more durable tips.

If you oversize the tips, you may lose efficiency unless you push the machine harder, which can shorten its lifespan.

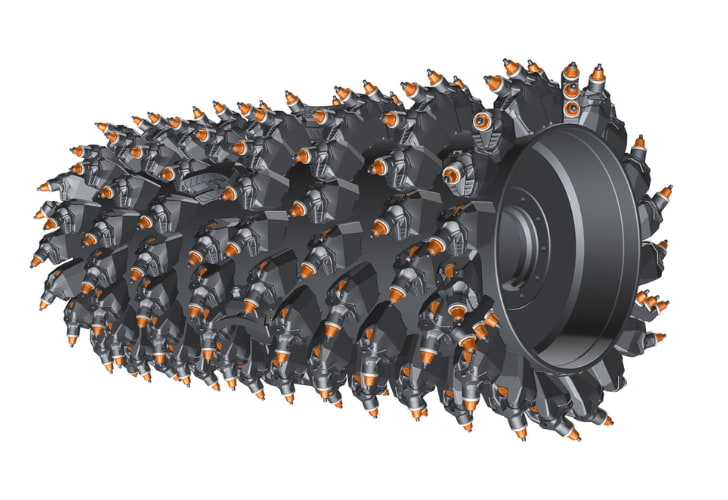

3. Consider the Milling Drum

(Image Source: wirtgen-group.com)

Not all drums are the same, and tooth selection should match their precision:

Standard milling drums: moderate resistance, good for general work.

Fine milling: needs higher cutting accuracy, so stronger teeth are a must.

Micro milling: very high tooth density, which spreads the impact but demands durable materials to avoid frequent replacements.

If you're using a precision drum, premium-grade teeth (beyond regular tungsten carbide) can make a big difference in lifespan and efficiency.

4. Factor in Milling Depth

Depth changes everything:

Shallow cuts: sharp teeth are more efficient.

Deep cuts: thicker, reinforced teeth hold up better under stress and heat.

5. Don't Forget Milling Speed

Running faster than the recommended speed? Go thicker. High speeds increase impact forces, making teeth more prone to breakage. Striking a balance between speed and tooth strength will keep you productive without burning through replacements.

6. Cost

Last but not least, it's about cost.

Longer teeth of the same thickness are less expensive, but have an increased lifespan, even if wear comes sooner. If your budget is sufficient, choose PCD teeth.

In short, choose your teeth based on material, machine power, drum type, milling depth, and speed. Balance that with your project budget. And when in doubt, talk with professionals for help.

Trusted brands of Road Milling Teeth

The easiest and most reliable way to select milling picks is to purchase from reputable manufacturers, including Wirtgen , Kennametal , Caterpillar , Sandvik , and BETEK . They design and manufacture top-quality carbide-tipped and PCD milling teeth for both asphalt and concrete milling.

*All of the above images are not intended for commercial use.