Tub grinders and horizontal grinders are the two common ways to turn woody material into mulch, compost feedstock, or biomass fuel. Generally speaking, tub grinders are more aggressive. They can swallow large stumps and logs and deliver very high throughput, but they carry higher safety, maintenance, and ownership costs. Horizontal grinders use a conveyor feed to produce a more uniform, controllable product, making them a better fit for composting and working near people or property.

(Image Source: vermeer.com)

Today, we'll walk through how each machine works, the real operating and ownership costs, safety trade-offs, and practical scenarios to help you decide which option suits your operation.

Tub Grinders vs. Horizontal Grinders: Feeding System and Material Size

Feeding system and incoming material size are often the single biggest drivers when you choose between a tub grinder and a horizontal grinder.

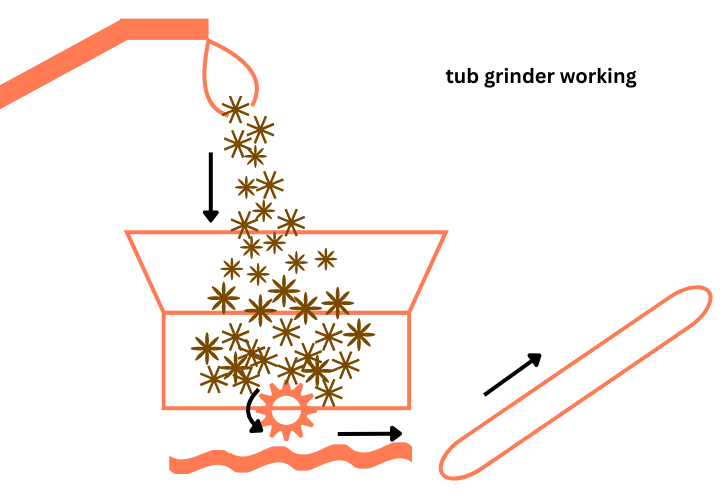

A tub grinder relies on a spinning, conical tub and gravity to feed material into the drum. The process is largely passive: heavy material naturally drops toward the drum, while lighter material, such as branches, may hover above and resist engagement. This creates an uneven flow. The result is a feed rate that fluctuates sharply, causing horsepower swings and the risk of plugging or lugging.

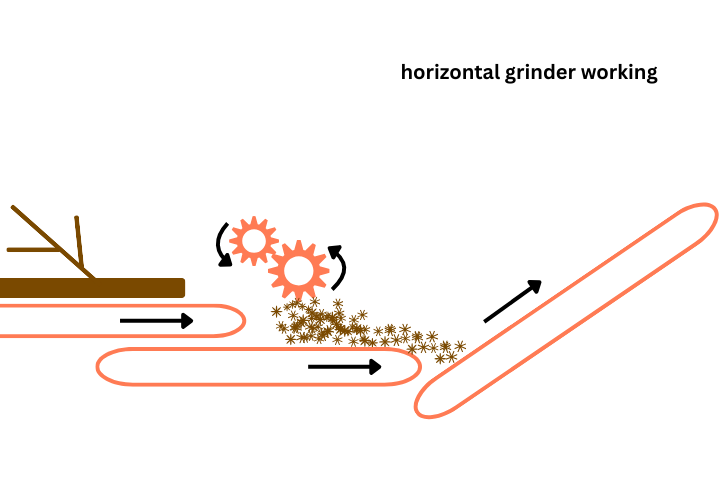

A horizontal grinder, on the other hand, uses a feed roller and a moving conveyor to deliver material into the drum. Here, the feed rate is actively managed. Operators can adjust roll speed and conveyor pace, or even reverse the feed if material enters too aggressively. This controlled system provides a steady, predictable flow and handles long pieces more efficiently.

As for the material size, tub grinders excel when dealing with bulky and irregular shapes, such as stumps, root balls, or pallets, thanks to the large tub opening. Horizontal grinders are better for long materials like tree trunks and branches, which can be laid onto the conveyor. For loose green waste, both machines work well.

Tub Grinders vs. Horizontal Grinders: Safety Considerations

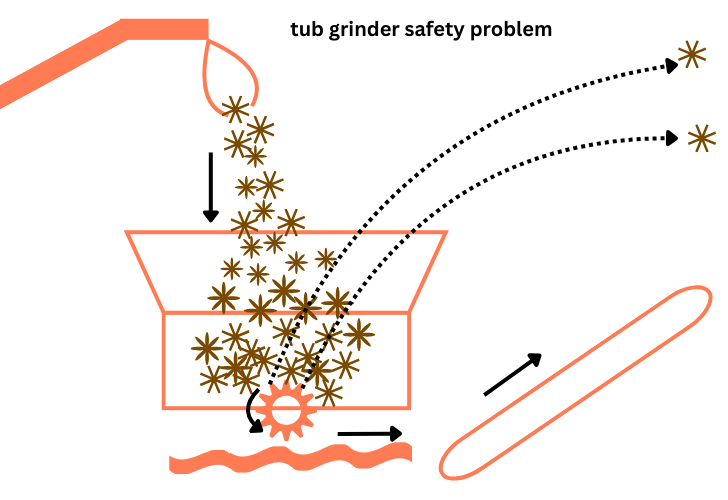

Generally speaking, tub grinders are more dangerous due to their open, spinning tub design. If the tub isn't fully loaded or the drum isn't covered, material can be ejected at high speeds. Operators must plan for large exclusion zones, sometimes several hundred feet, around the machine and keep bystanders and other equipment well clear. Safety features like the Thrown Object Restraint System (TORS) help reduce risks, but they cannot eliminate them. A tub grinder also demands experienced operators and a maintenance-ready crew to handle potential mechanical issues from errant material like steel.

Horizontal grinders, by contrast, offer a more controlled and confined operation. The feed system, powered rollers, and a moving floor push material steadily into a partially enclosed drum. As a result, any thrown material is limited to a forward and slightly outward area from the feed opening, significantly reducing the hazard zone. While hidden metal can still cause damage, modern machines often include automatic feed reversal or shutdown systems to minimize the risk. For jobsites with space constraints, nearby structures, or people, horizontal grinders are generally the safer, more manageable choice.

Tub Grinders vs. Horizontal Grinders: Finished Product

Because of the controlled feed and adjustable screens, horizontal grinders deliver more consistent particle sizes and can produce finer material when needed, ideal for landscape mulch, compost, or animal bedding. Tub grinders tend to produce coarser, less uniform material.

As several forum contributors note, the choice often depends on the material and purpose: if you'll process various irregular material and can accept variability, the tub wins; if you'll deal with long materials and need a precise, consistent product for composting or resale, the horizontal grinder is usually the better fit.

Tub Grinders vs. Horizontal Grinders: Transportability

Horizontal grinders often come with tracks, which make them easy to move around a site. This feature is especially valuable for land clearing, modular operations, or projects where the grinder needs to be repositioned frequently. The tracks allow operators to move the machine over uneven terrain without relying on additional equipment.

Tub grinders, by contrast, are generally stationary machines. While many models can fold their sides for transport and comply with road width restrictions, they lack integrated tracks, making on-site movement more challenging. However, tub grinders without a loader are usually lighter than a comparable horizontal grinder, which can reduce transportation costs when moving the machine between sites.

Tub Grinders vs. Horizontal Grinders: Maintenance

Tub grinders are often called “expensive pigs” for good reason. The initial purchase price is high, and ongoing maintenance can quickly add up. Operators frequently encounter mechanical issues, from worn rotor teeth to damaged screens, which require time, skill, and costly parts to repair.

(Image Source: vermeer.com)

Horizontal grinders, in comparison, are generally easier and less expensive to maintain. Fewer moving parts and a more controlled feeding system reduce some of the wear and tear seen in tubs. That said, horizontals have their own vulnerabilities. Material contaminated with steel or other hard objects can cause significant internal damage, sometimes requiring costly repairs.

(Image Source: vermeer.com)

Practical Tips

- A good dealer can make a huge difference when it comes to owning and operating a grinder. Modern grinders can produce hundreds of tons per hour, but downtime quickly reduces both production and profitability. That's why support should be a top priority when choosing equipment. A reliable dealer ensures parts are available locally or can be shipped quickly, provides expert advice on machine selection, and helps make the most out of your grinder. They can also guide you in finding end markets for your product and offer financing options. Doing your homework, asking questions, and speaking with current customers will help you find a dealer who not only sells a machine but also helps you keep it running efficiently and cost-effectively.

- When deciding how to handle the grinding job, you have three main options: purchase, rent, or outsource. Buying makes sense if you have consistent high-volume work and the expertise to maintain the machine. Renting can be a flexible choice for short-term projects, but watch for rental terms and who is responsible for repairs. Outsourcing to a specialized contractor is often the easiest way to get the job done without the headaches of ownership, especially for smaller operations or irregular workloads. Each option has trade-offs, so consider your budget, volume, and long-term plans before committing.

- For smaller-scale composting or yard waste projects, there are practical alternatives to large grinders. A brush mower working with a wood chipper can handle branches. Small horizontal grinders, like compact Vermeer models, work well for regrinding material into finer particles. If your goal is simply creating ground cover or mulch, there's often no need to invest in a large machine. These smaller, more manageable options can get the job done perfectly.

Final Thought

Both tub grinders and horizontal grinders have their strengths, and the right choice depends on your specific needs. Over the years, horizontal grinders have steadily gained popularity, increasingly favored for their safety, mobility, and precision. When it's time to add or replace a grinder, understanding your workflow and long-term goals will help you select the machine that best fits your projects.

*All of the above images are not intended for commercial use.