Whether you're exploring options for industrial tools or browsing for a durable wedding ring, chances are you've come across tungsten and tungsten carbide, and maybe even assumed they were the same thing.

Although these two terms are sometimes used interchangeably, especially in the jewelry world, they are chemically very different materials. In fact, understanding tungsten vs. tungsten carbide can help you make smarter decisions, especially in high-performance or high-wear situations.

(Image Source: amanatool.com)

Today, we'll break down the key distinctions between these two heavyweights in a clear, practical way, no materials science degree required. And yes, we'll briefly touch on what all this means if you're shopping for a tungsten ring, too.

Tungsten vs. Tungsten Carbide: Definitions

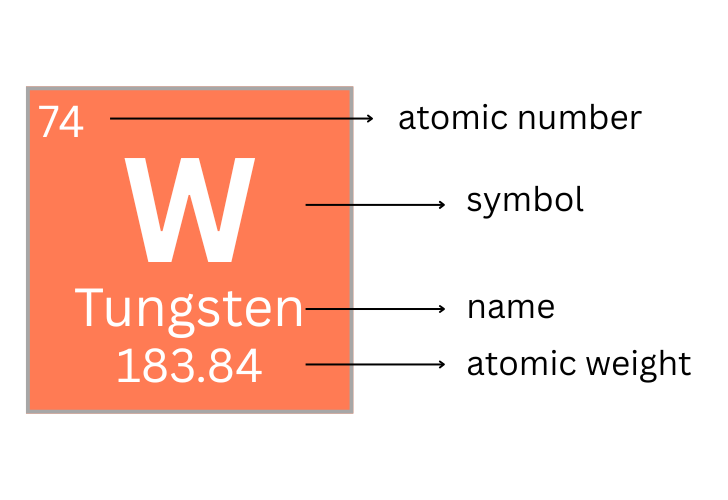

Tungsten: Solid tungsten has atomic number 74 on the periodic table of the elements, featuring a dark grey color and outstanding hardness (a Vickers hardness of 3430-4600 MPa). It has an extremely high melting point of 6,192°F (3,422°C), the highest of all known elements, making it required in high-temperature applications like filaments. Due to its high density and hardness, pure tungsten is difficult to press and shape. As a result, it is often mixed with other materials, forming alloys.

Tungsten Carbide: Tungsten carbide, or carbide, is a chemical compound of tungsten carbide (WC, tungsten and carbon) powder and a binder material (usually cobalt or nickel). The accurate term is "cemented tungsten carbide," but in most industries, people simply call it "carbide." With outstanding high hardness (9.0-9.5 on the Mohs scale), corrosion resistance, and wear resistance, carbide is popular in various industries, including metal cutting, construction, oil & gas, forestry, recycling, wear parts, aerospace, jewelry, etc.

Tungsten vs. Tungsten Carbide: Properties

When comparing tungsten vs tungsten carbide, their physical and mechanical differences are more than just technical; they directly impact how each material performs in real-world applications.

Hardness & Scratch Resistance

This is one of the most noticeable differences. On the Mohs scale, pure tungsten has a hardness of around 7.5-8, which is impressive but still susceptible to scratching under heavy wear. Tungsten carbide, on the other hand, is significantly harder, scoring around 9, only second to diamond. This makes tungsten carbide extremely scratch-resistant, a key reason why it's widely used in cutting tools, machining equipment, and scratch-proof rings.

Brittleness vs Toughness

While tungsten carbide is exceptionally hard, that comes with a trade-off: it's also more brittle. This means it can crack or shatter if subjected to a sudden, sharp impact, something to keep in mind, especially for jewelry or handheld tools. In contrast, pure tungsten, though softer, is tougher and less prone to breaking, giving it an edge in applications where some flexibility or impact resistance is required.

Heat Resistance

Tungsten is famous for its heat tolerance; it has the highest melting point. That's why it's commonly used in high-temperature environments like filaments, heating elements, and aerospace components. Tungsten carbide still offers strong heat resistance, with a melting point around 5,045-5,126°F (2,785-2,830°C), but it falls slightly behind pure tungsten in this aspect.

Density

In terms of weight, tungsten is heavier, with a density of 19.254 g/cm³, giving it a very solid, weighty feel. Tungsten carbide is slightly less dense, averaging around 15.6 g/cm³, but still substantial enough to feel premium, especially in products like rings or industrial tools where heft is often associated with durability.

Tungsten vs. Tungsten Carbide: Selection Guide

When choosing between tungsten vs tungsten carbide, the best option really depends on what your project or product demands. While both materials are known for their strength and durability, they excel in different areas. Here are a few key factors to consider when making your decision:

Need maximum hardness and wear resistance?

Go with tungsten carbide. Thanks to its exceptional hardness, it's the better choice for applications that involve frequent friction, abrasion, or cutting. That's why it's the ideal material for industrial drill bits, cutting tools, and scratch-resistant rings. If durability under wear is your top priority, tungsten carbide won't disappoint.

Working in high-heat environments?

Pure tungsten is the better fit here. With a melting point over 3,400°C, it performs exceptionally well in extreme-temperature settings, like aerospace parts, heating elements, and electrical applications where thermal resistance is critical.

Concerned about impact resistance?

While tungsten carbide is harder, it's also more brittle. If your application involves potential impact or shock, pure tungsten or a tungsten alloy with added ductility may offer better toughness and reliability.

Shopping for jewelry?

(Image Source: unsplash.com)

If you're looking at tungsten rings, chances are you're actually shopping for tungsten carbide, even if it's labeled simply as "tungsten." Most rings marketed as tungsten are made from tungsten carbide because it offers better scratch resistance and finish retention. Just make sure the product description clearly states the material.

Budget considerations

Tungsten carbide can be more expensive upfront, but its longer wear life may save you money in the long run, especially if you're using it for tools or parts that would otherwise wear out quickly. On the other hand, pure tungsten is typically more affordable but might require replacement sooner, depending on the application.

Customization needs

Both tungsten and tungsten carbide can be customized according to specific requirements, but due to their hardness, it's essential to work with a supplier who understands the subtle differences in processing these materials. Don't hesitate to ask questions about the production process; a knowledgeable supplier can make all the difference.

Conclusion

Understanding the real differences in composition, durability, and performance between tungsten vs. tungsten carbide can help you choose the right material, whether you're sourcing wear parts for an industrial project or shopping for a wedding band that lasts a lifetime. In the end, it's all about matching the right material to the job. And now, you've got the knowledge to do just that.

*All of the above images are not intended for commercial use.