Winter landscapes can be stunning, with trees dusted in white, quiet streets, and that fresh, crisp air. But once the snowfall piles up, beauty quickly turns into a challenge. Roads get slippery, driveways disappear under inches of snow, and everyday routines can come to a halt. That's where snow plows come in. They keep our roads safe and our communities moving. And at the heart of every snow plow is its blade. Choosing the right type of snow plow blade isn't just about equipment; it's about efficiency, durability, and safety.

(Image Source: Photo by Māris Prūsis on Unsplash.com)

So, today, let's explore different types of snow plow blades. We'll look at them from two different angles: their designs and the materials they're made from.

Types of Snow Plow Blades by Design

Straight Blade Plows

(Image Source: westernplows.com)

When most people picture a snow plow, they're probably thinking of the straight blade. It's the classic, basic design, a single straight edge that can push snow forward or angle slightly left and right to clear a path. Because of this simplicity, straight blades are the most widely used type of plow, found everywhere from neighborhood driveways to busy municipal roads.

A straight blade is easy to operate and maintain, so both beginners and pros can handle it. Plus, with a simpler design and fewer components, a straight blade plow is more affordable compared to other designs. It's versatile and can be mounted on various vehicles, from pickup trucks or SUVs to heavy-duty trucks. A straight blade is even handy for pulling snow away from garage doors or tight spots (known as backdragging).

Things to keep in mind:

Straight blades aren't perfect for every situation. Because they mostly push snow straight ahead or to the side, you might need multiple passes to get a clean finish. They can also struggle in very deep or extremely heavy snow, where more specialized plows (like V-plows) might perform better.

V-Blade Plows

(Image Source: westernplows.com)

If the straight blade is the "classic," then the V-plow is the multitasker of the snow removal world. Designed with two wings that form a "V" shape, this blade can switch between different positions, V, straight, or scoop, depending on the job. That flexibility makes it especially valuable when conditions get tough.

The V position cuts straight through deep, packed snow like a knife, while the scoop position is great for carrying and clearing large amounts of snow in fewer passes. You can also run it in straight mode when you just need a standard push.

Things to keep in mind:

The versatility comes at a price, literally. V-plows usually cost more than straight blades, and they're heavier too, which means you'll need a strong vehicle to handle the extra weight. Plus, learning to switch smoothly between positions takes a bit of skill, so they're better suited to experienced operators or commercial use.

Expandable Snow Plows

(Image Source: westernplows.com)

Unlike a fixed straight or scoop blade, these plows can extend outward to cover more ground or pull back in when space gets tight. That adjustment makes them incredibly efficient for a wide range of jobs. The widened blade can clear large open areas like parking lots in fewer passes, saving both time and fuel.

Things to keep in mind:

Expandable plows are advanced equipment. They're heavier, more complex, and usually require a powerful vehicle to handle the load. Operators also need some training to get comfortable switching between positions. On top of that, they are more expensive, which makes them more common in commercial fleets than in residential driveways.

Specialty Snow Plows

(Image Source: blackcatwearparts.com)

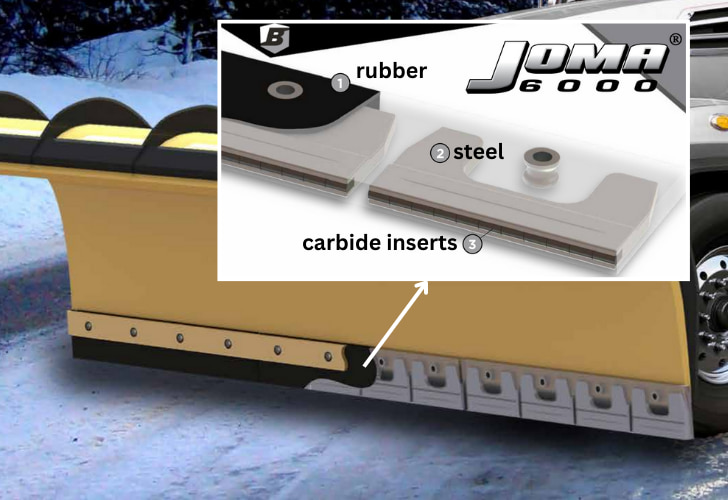

Black Cat's specialty designs push snow plow technology a step further.

The JOMA 6000 stands out with its unique construction, tungsten carbide inserts set in profiled steel segments, all encased in rubber. This unique design dramatically extends its wear life compared to standard carbide blades. The rubber casing absorbs vibration and road shock, reducing operator fatigue, noise, and maintenance costs. It also minimizes blade bounce, protecting road markings while allowing the blade to follow the road contour more closely. The result is smoother, quieter plowing, cleaner road surfaces, and reduced reliance on salt and sand.

The SnoShock™ series takes a different approach by integrating shock absorbers directly into the blade. Instead of transferring impacts straight through the plow, the cushioned mount absorbs the force, virtually eliminating carbide fracturing. Combined with extra-large tungsten carbide inserts and a hardened face shield, SnoShock blades deliver exceptional durability and protection against premature wear, making them a reliable choice for demanding snow-clearing conditions.

Together, these specialty designs show how much difference blade materials can make. Next, let's take a closer look at various snow plow cutting edge materials.

Types of Snow Plow Blades by Material

Rubber Snow Plow Cutting Edges

(Image Source: rubbercal.com)

Made from natural and synthetic rubber blends, rubber snow plow cutting edges are extremely flexible. They glide over decorative pavement, parking garages, or other sensitive surfaces without leaving scratches or gouges. They also run much quieter than steel, which makes them a good fit for residential neighborhoods or places where noise is a concern.

That said, rubber isn't as tough as steel or carbide. These blades wear down faster and don't scrape away hard-packed snow or ice as effectively. As a result, you might need to use more salt or ice melt to get a clean surface. Because of the higher replacement cycle, rubber snow plow blades are usually reserved for specialty jobs where surface protection matters more than aggressive scraping power.

Polyurethane Snow Plow Cutting Edges

(Image Source: store.fallline.com)

Polyurethane, often shortened to poly, sits right between rubber and steel when it comes to performance. It's tougher and longer-lasting than rubber, yet gentler on surfaces than steel. This makes it a true "middle-of-the-road" option for plowing delicate or decorative areas like shopping centers, banks, or residential driveways. Poly snow plow blades are stiff enough to give a decent scrape while still flexible enough to reduce vibration and noise. So, the operator can work in a relatively comfortable and quiet environment. Poly cutting edges also strike a balance between durability and surface protection, lasting longer than rubber but not quite as long as steel.

On the downside, polyurethane blades are usually more expensive, and their quality (and price) can vary depending on the material blend. Still, for many contractors, the investment pays off with reduced surface damage, smoother operation, and fewer replacements compared to rubber edges.

Carbide Snow Plow Cutting Edges

(Image Source: blackcatwearparts.com)

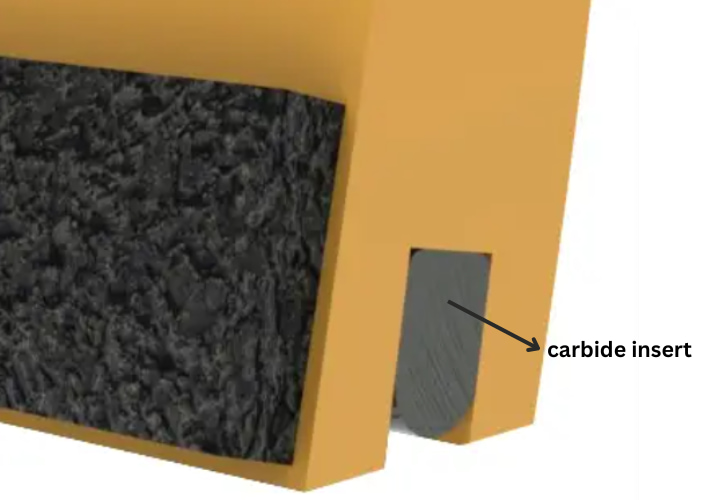

Carbide cutting edges look a lot like steel blades at first glance, but they're actually a combination of a steel base with a tungsten carbide insert brazed into the steel along the bottom of the blade. This design gives them incredible wear resistance, making them one of the most durable options available. They're especially effective for cutting through ice and deep, heavy snow, and they hold up far longer than traditional steel edges.

However, carbide edges are more expensive than other types of cutting edges. Because tungsten carbide is extremely hard but also brittle, the steel backing is essential to protect it from breaking under impact. They can also be tough on road surfaces, which is why they're mainly used on highways and other areas that are frequently repaved.

Steel Snow Plow Cutting Edges

(Image Source: westernplows.com)

Steel is the most common material for snow plow blades. It's durable, widely available, and offers excellent scraping power, making it ideal for clearing packed snow and ice without relying heavily on salt or chemical treatments. High-carbon steel, in particular, provides extra strength and longevity, which is why many municipalities and commercial operators choose it for harsh conditions and abrasive surfaces.

Steel cutting edges do wear faster than harder materials like carbide or specialty steels, and their aggressive scraping can sometimes damage road surfaces. They're also heavier, which can affect fuel efficiency and plow performance on smaller vehicles. Despite these considerations, steel edges remain a reliable, high-performance choice for large areas or applications where noise and surface sensitivity are less of a concern.

Bottom line: Choosing the right material comes down to the conditions you face and the surfaces you need to protect. For light, quiet, surface-sensitive work, rubber or poly is ideal, while steel and carbide excel in tougher, high-volume snow removal tasks.

*All of the above images are not intended for commercial use.