When I first joined a tungsten carbide trading company, I remember staring at the catalog and feeling completely lost. There were all these mysterious codes, C2, C10, K20, K30…, and every supplier claimed their grade was "the best." I wondered: What exactly is a carbide grade? Why are there so many of them? And how am I supposed to pick the right one for my customer's application?

(Background Image Source: Photo by Steve Johnson on Unsplash.com)

If you've ever felt the same way, you're not alone. The world of tungsten carbide can seem overly technical at first, but once you understand the logic behind grade designations, it all starts to make sense. Let's start with the basics.

What Are the Grades of Tungsten Carbide?

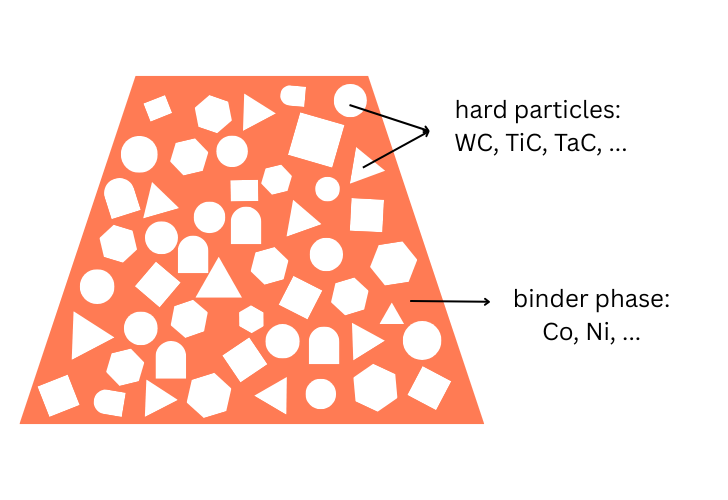

A grade is a specific formulation of tungsten carbide powder, binder metal (usually cobalt), and processing method. It's like a recipe. Each grade combines these ingredients in different proportions and grain sizes to achieve a particular balance of hardness, toughness, and wear resistance.

The purpose of having grades is to create a common language between buyers, users, and manufacturers, especially in the carbide blanks industry. A grade is a unified label that represents a set of properties. This means no one has to describe the composition, hardness, and strength from scratch every time. Key parameters in a grade chart include WC%, Co%, other content, grain size, hardness, density, and transverse rupture strength.

Why Are There So Many Grades?

You might wonder: "Do we really need that many tungsten carbide grades?"

Actually, the large number of grades reflects how diverse the working environments are, and how every application involves a trade-off between different material properties.

The balance between hardness and toughness

A harder grade usually offers better wear resistance but tends to be more brittle. It may crack or chip under heavy impact. A tougher grade, on the other hand, can handle shock and vibration better but will wear out faster because it's not as hard. Different jobs demand different compromises.

Different applications, different priorities

Cutting tools, forming dies, wear parts, and mining tools all have different priorities when it comes to material performance. A precision cutting insert needs extreme hardness and edge stability for accurate machining. A mining drill bit, by contrast, must survive constant impact, vibration, and fracture risk.

Manufacturer and market differentiation

Each manufacturer also develops its own grade system to cover a wider range of customer needs or to build competitive differentiation. So even if two companies make similar products, their grade codes and compositions may not be identical.

Non-unified standards

Although there are global systems like the US "C" designation, the ISO designation, and other designations, none of them fully standardize the naming or classification.

As CUTTING TOOL ENGINEERING Magazine explained in Knowing the basics of tungsten carbide grades, carbide grades are often grouped by their machining purpose:

"Straight grades can be classified as C1 to C4. Tougher grades with coarser grain sizes or higher cobalt content are used for roughing, such as C1 or K30. Harder grades with finer grains or lower cobalt are used for precision machining, like C4 or K01."

Common Classification Systems of Tungsten Carbide Grades

The ANSI C-system

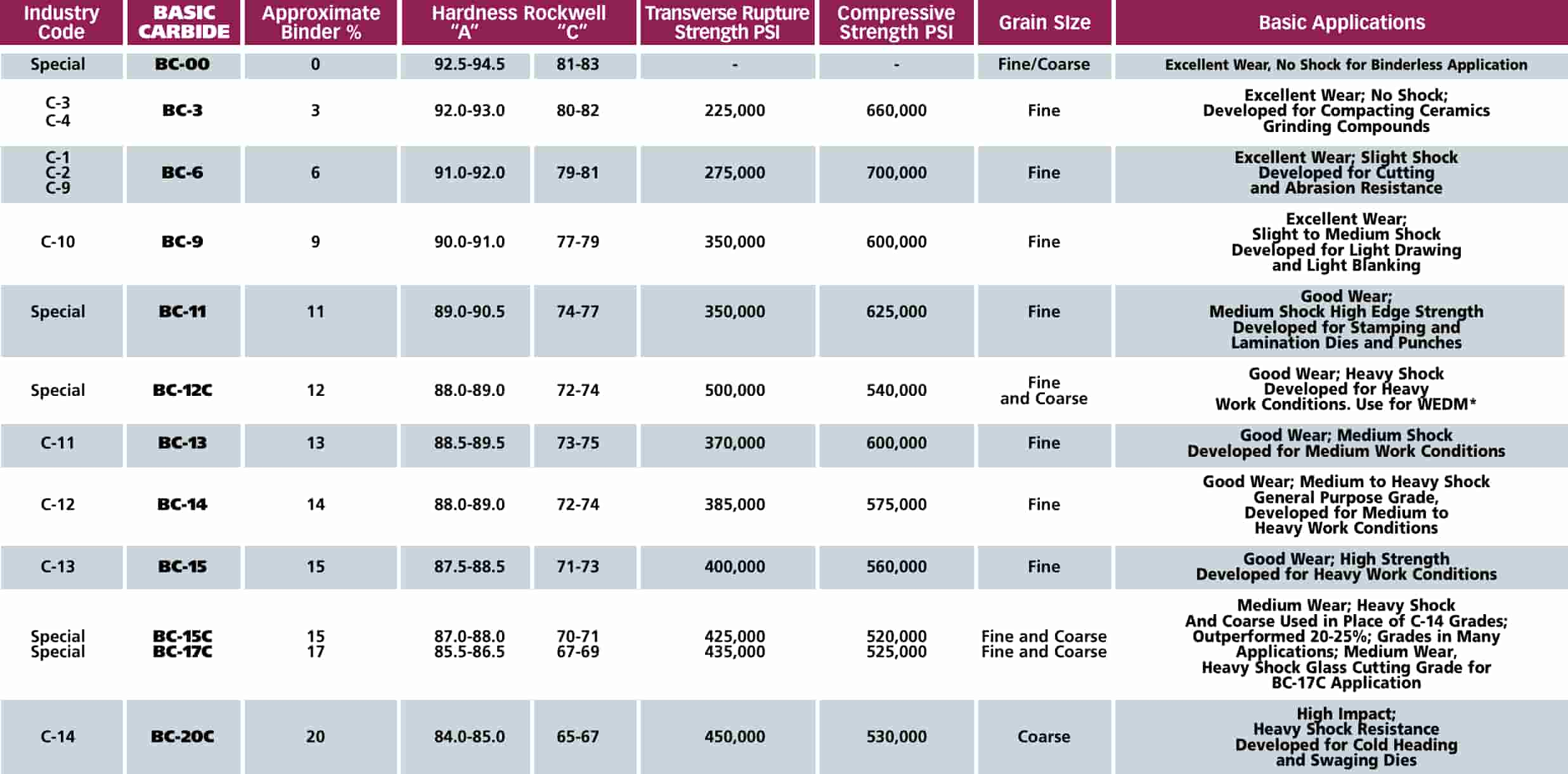

This is a common naming system in the wear parts, mold, and general-purpose carbide markets, especially among U.S. suppliers and general alloy or wear-resistant component manufacturers.

For example, in Basic Carbide's Tungsten Carbide Grade Chart, grades such as C-1, C-2, C-3, C-10, and C-12 are listed along with their approximate cobalt content, hardness, transverse rupture strength, and typical applications (such as wear parts, molds, and impact-resistant components).

(Image Source: Basiccarbide.com)

In Carbide Processors' "Tungsten Carbide Grades", grades C1 to C4 are categorized by general machining purposes:

- C-1: Roughing

- C-2: General Purpose

- C-3: Finishing

- C-4: Precision

In addition, grades like C9, C10, C11, and C12 are listed for different shock and wear levels (for example: no shock, light shock, heavy shock).

(Source: Carbide Processors)

The advantage of this naming system is that it's straightforward to communicate. The drawback is that it's not an internationally unified standard, so the exact meanings of these codes may vary slightly between manufacturers.

The ISO classification system

In the cutting tool and metal machining field, a common classification system is the ISO P / M / K series, often followed by a numerical grade suffix.

(Image Source: carbidedepot.com)

These categories mainly apply to tungsten carbide grades used in cutting tools.

- P-type: for cutting steels and low-alloy steels, which are relatively ductile metals

- M-type: for cutting stainless steels

- K-type: for cast irons, non-ferrous metals, and hard or brittle materials

The numerical suffix (such as P10, P20, K05, K20, K30) represents the performance level within that category, indicating whether the grade is more wear-resistant, tougher, or balanced.

It's important to note that this classification system is mainly used in cutting tools. In other fields, such as molds, wear parts, mining tools, or impact-resistant components, it may not be the dominant system, though it's sometimes used for reference or cross-comparison.

Cross-Reference and Compatibility Issues

Because there are many systems and naming conventions, as a buyer or user, you often need to create a cross-reference table. Many grades have "approximate equivalents" between different manufacturers or systems. For example, one company's C10 may have similar properties to another company's K30.

How to Select the Right Tungsten Carbide Grade

Here is a selection process that I've summarized from years of practical experience, from understanding working conditions to verifying samples.

Step 1: Identify Your Application Type and Working Conditions

First of all, you need to answer these questions:

- What is your part or tool used for? Cutting, forming, wear resistance, mold making, impact resistance, mining, drilling, or stamping?

- In this application, which performance factor is most critical, wear resistance (hardness) or impact/crack resistance (toughness)?

- What is the working environment like? Are there vibrations, shocks, high temperatures, lubrication, corrosion, abrasive particles, strong cutting forces, or interrupted cutting?

These factors determine whether you should choose a hard/wear-resistant grade, a tough/impact-resistant grade, or something in between.

Step 2: Filter Key Parameters Based on Working Conditions

Once the application type is clear, you can use the following parameters as screening criteria:

1. Cobalt Content (%)

Lower cobalt → harder, more wear-resistant;

Higher cobalt → better toughness and crack resistance.

Don't reduce cobalt too much, or it may fracture under vibration or impact.

2. Grain Size

Fine grain → higher hardness and better surface finish;

coarse grain → stronger impact resistance.

Very coarse grains may cause instability or crack sensitivity at the surface.

3. Hardness / Transverse Rupture Strength

Key indicators to evaluate whether the grade can withstand load and resist fracture. Don't focus only on hardness; also check TRS and toughness values.

4. Density / Porosity

High porosity greatly reduces fatigue life. Ask the supplier for microstructure images, density ratio, or inspection reports.

Step 3: Select Candidates from Manufacturer's Tungsten Carbide Grade Chart

Once you have the target parameters, refer to the manufacturer's grade chart. Let's say, you're selecting a reliable carbide blanks or preforms supplier. Compare cobalt content, grain size, hardness, and TRS values to pick several grades that meet your requirements in both performance and price/availability.

Remember: you don't need to find the "perfect" grade. It rarely exists. Just choose one that offers a reasonable balance for your working conditions and is practical in terms of cost and availability.

Step 4: Sample Testing and Validation

Even if you make a careful selection, it's always recommended to do sample testing or small-batch trials. Theoretical data often differ from real-world performance. Here are some suggestions:

- Test the sample under actual working conditions and observe service life, wear, and fracture behavior.

- If possible, conduct accelerated fatigue or impact tests.

- Compare the results with your previous grade or existing solution.

- Record failure modes and lifetime data, then share feedback with the supplier for optimization.

This stage is extremely important. Many purchasing failures happen because they skip this step, and jump straight into mass production, and regretting later when issues arise.

Practical Tips

Here are some practical tips I've summarized from my previous experience:

- Don't judge by grade names alone. Always look at the cobalt content, hardness, TRS, grain size, and other technical parameters.

- Request complete datasheets and microstructure information from suppliers.

- Whenever you encounter a new supplier or a new grade, record its properties and create a reference grade chart for future comparison.

- Even if the technical parameters look right on paper, test the grade under actual working conditions first.

- Overemphasizing one property, for example, maximum hardness or lowest cost, often compromises lifetime and reliability.

- Sometimes choosing a slightly more expensive, more durable grade is actually more economical in terms of service life and failure costs.

- Pay attention to coatings, post-processing, or surface treatments. Often, the same base grade with different coatings or surface treatments can produce very different results.

Conclusion

Looking back, when I first started working with tungsten carbide grades, I was easily confused about codes like C2 or K20. I later realized that what really matters are the parameters, the trade-offs in performance, and how well the grade matches the working conditions.

*All of the above images are not intended for commercial use.