For professionals in the carbide industry, especially engineers or purchasing managers, carbide blanks are probably one of the most familiar products. Among all carbide products, carbide blanks stand out because they are the starting point of countless cutting tools and wear parts. The performance of the finished product largely depends on the quality of the blank itself.

Premium tungsten carbide blanks ensure consistent hardness, wear resistance, and dimensional stability. That is why carbide blanks are widely used across industries where precision and durability matter.

Today, we will discuss what carbide blanks are, why carbide rods are the most commonly used, what carbide blanks are used for in real-world applications, and how to choose the right blank for your needs. Let's get started!

What Are Carbide Blanks?

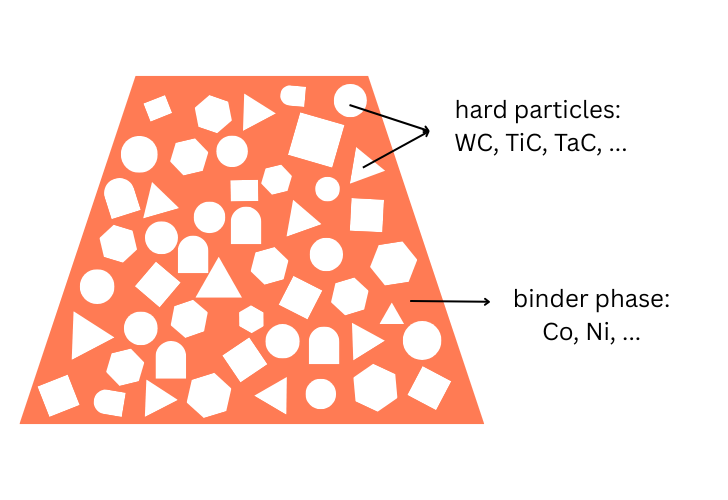

Carbide blanks are semi-finished products made through a powder metallurgy process. In simple terms, tungsten carbide powder is mixed with a metallic binder, most commonly cobalt, then pressed and sintered at high temperature to form a solid piece. The result is a blank with a predefined shape, such as rods, plates, strips, or blocks.

At this stage, carbide blanks already possess the core properties of cemented carbide : extremely high hardness and excellent wear resistance. However, they are not ready for direct use. The surface finish is relatively rough, and the dimensional accuracy is limited. Further precision machining is required before they can become cutting tools, molds, or wear parts.

So why not produce finished tools directly? The reason lies in the nature of carbide itself. Like ceramics, tungsten carbide is very hard but also brittle, making conventional turning or milling inefficient and impractical. By producing carbide blanks that are close to the final geometry, manufacturers can rely on grinding with diamond wheels or EDM for finishing. This approach improves machining efficiency and minimizes material waste.

Why Carbide Rods Are the Most Common Carbide Blanks?

Among all carbide blanks, carbide rods are by far the most widely used. A carbide rod is a cylindrical tungsten carbide blank, also known as a carbide round bar or carbide rod blank. It is produced to meet the needs of tool manufacturers, who further machine these rods into finished cutting tools, such as end mills, drills, boring tools, and reamers. Thanks to their relatively simple geometry and suitability for precision grinding, carbide rods have become the most common starting form in tool manufacturing.

(Image Source: Photo by gefrorene_wand on pixabay.com)

Carbide rods come in various types to match different tooling requirements. Based on structure, there are solid carbide rods and carbide rods with coolant holes. Coolant-hole rods can feature straight or helical holes, with one hole or multiple holes, depending on cutting performance and chip evacuation needs. Another common variation is chamfered carbide rods, which help reduce edge chipping during handling and subsequent machining.

Carbide rods can also be classified by surface condition. Ground carbide rods offer tighter dimensional tolerance and smoother surfaces, while unground carbide rods are typically used when further grinding is planned by the tool manufacturer.

Because carbide rods vary greatly in structure and processing complexity, not all carbide rod manufacturers offer the same level of capability. Some suppliers can produce rods with complex internal hole designs or challenging hole angles, while others cannot. For tool makers, choosing the right cemented carbide rod supplier is critical, as the quality and consistency of the rod directly affect tool performance and machining results.

What Are Carbide Blanks Used For?

Although tungsten carbide blanks are used in countless industries, most applications are built on two core properties: extremely high hardness and outstanding wear resistance. In other words, carbide blanks are either used to cut and shape other materials or to protect key parts of equipment in harsh working conditions.

Based on how carbide blanks are actually used in manufacturing and engineering, their applications can be grouped into four main areas.

1. Metal Cutting and Machining

Metal cutting is by far the largest and most important application of carbide blanks. In CNC machining, carbide blanks are processed into indexable inserts with standard shapes such as triangles, squares, or rounds. After precision grinding, sharp cutting edges and complex chip breakers are created. These inserts are widely used for turning, milling, and grooving operations.

(Image Source: Photo by blickpixel on pixabay.com)

Carbide rod blanks are also ground into solid cutting tools, including drill bits, end mills, and reamers, as we mentioned earlier. These tools are essential for machining precision holes, complex cavities, and tight-tolerance components. Industries such as mold making, aerospace, and precision mechanical manufacturing rely heavily on these tools to maintain consistency and productivity.

2. Mining, Drilling, and Exploration

In mining and drilling, carbide blanks are used in components that directly contact rock and other highly abrasive materials.

A common example is rock drilling bits, such as roller cone bits and DTH bits. Carbide blanks are shaped into buttons or teeth and brazed onto drill heads. These carbide teeth are responsible for crushing and breaking rock formations in surface mining, underground mining, and tunneling operations.

Carbide is also used in cutting picks mounted on roadheaders and coal mining machines. These picks continuously cut coal or rock under heavy impact and friction. In geological exploration, carbide-tipped drill bits are used to extract core samples for analysis.

3. Material Forming and Drawing Dies

Another major use of carbide blanks is in forming and shaping metals, especially in die applications.

Wire drawing dies are a classic example. Carbide blanks are machined to create an extremely smooth and wear-resistant central hole. Metal wires such as copper, aluminum, and steel are pulled through this hole under high tension to reduce diameter and achieve precise sizing. Without carbide dies, large-scale production of wires, cables, and tire cords would not be possible.

Carbide is also widely used in cold heading and stamping dies. These dies are used to mass-produce fasteners like screws, bolts, nuts, and rivets at very high speeds. Compared to steel dies, carbide dies offer dramatically longer service life and ensure stable part dimensions during continuous production.

4. Wear-Resistant Components

Carbide blanks are often used to produce wear parts that protect equipment in areas exposed to severe friction, erosion, or impact.

Typical examples include seal rings and bushings used in oil drilling equipment, chemical pumps, and high-pressure water pumps. In environments involving sand, high pressure, or high temperatures, carbide components help maintain sealing performance and prevent leakage.

Other applications include rollers and guides used in wire and bar rolling lines, where hot metal is guided and shaped under heavy load. Carbide nozzles are also common in sandblasting and water jet cutting systems, where high-speed abrasive flow would quickly wear down conventional materials.

How to Choose the Right Carbide Blanks?

Carbide blanks may look similar at first glance, but choosing the wrong one can lead to poor performance, short tool life, or unnecessary cost. Before contacting carbide blanks suppliers or manufacturers , it is important to be clear about what you actually need. Here are several key factors to consider when selecting the right tungsten carbide blanks or cemented carbide blanks.

1. Start with the Application

The first question is simple: what will the carbide blank be used for?

Some carbide blanks are designed for cutting and machining, while others are meant for wear-resistant parts. These two uses place very different demands on carbide properties. Cutting tools focus more on hardness and edge retention. Wear parts require a balance between wear resistance and toughness to survive long-term friction or impact. Once the application is clear, the range of suitable carbide grades becomes much narrower.

2. Material Being Processed

The next step is to look at the material the carbide blank will face.

Machining steel, aluminum, wood, or composite materials requires different carbide characteristics. Harder and more abrasive materials usually demand higher wear resistance, while softer materials may benefit from tougher grades that reduce chipping.

The same logic applies to non-cutting applications. Carbide used against rock, sand, or slurry needs a different performance than carbide used in clean, controlled environments.

3. Carbide Grade

Carbide grade selection is one of the most important decisions.

Different carbide grades vary in hardness , toughness, and heat resistance. Grades with higher hardness generally perform better in high-speed cutting or abrasive conditions, but they may be more brittle. Tougher grades can handle impact and vibration better, though they may wear faster.

Reliable suppliers usually offer their own grade systems. Understanding what each grade is designed for helps avoid over-specifying or under-specifying the material.

4. Size and Shape

Carbide blanks come in many forms, such as rods, plates, strips, and custom preforms.

The correct size depends on the final tool or part and the machining allowance required. Oversized blanks increase grinding time and cost, while undersized blanks limit processing options. Shape selection is equally important. Straight cuts, curved profiles, or complex geometries all require different blank forms. Clear drawings or specifications help carbide factories provide the most suitable solution.

5. Evaluate the Supplier's Capabilities

Choosing the right carbide blanks suppliers is just as important as choosing the material itself.

Check whether the supplier holds quality certifications such as ISO. Understand whether they control the full production process, from powder preparation to carbide sintering, or if they rely on outsourced materials. Manufacturers with in-house sintering and stable production equipment usually offer more consistent quality.

Other practical factors also matter, including customization options, sample availability, lead time, logistics, and after-sales support. A carbide blanks manufacturer should be able to answer these questions clearly and professionally.

Conclusion

Carbide blanks are the foundation of almost all tungsten carbide cutting tools and wear parts. For buyers aiming to produce durable and efficient tools or wear parts, selecting carbide blanks should never be a casual decision. Clarifying application needs, comparing different carbide grades, and evaluating multiple carbide blanks suppliers are all necessary steps. After all, carbide blanks are rarely a one-time purchase, and the right choice directly affects long-term cost and performance.