Whether it's a land clearing job or a green waste recycling project, a horizontal grinder is an important tool. It's designed to grind and cut trees, stumps, logs, and other wood waste into usable chips, mulch, or biomass. Compared to tub grinders, horizontal grinders are safer and more controlled and can deliver a more consistent output.

If you're new to this type of machine, you might be wondering about a lot of things: how it works, its pros and cons, how to choose the right model, how to maintain, which brands are worth considering, and horizontal vs. tub.

We'll cover all of that here. Let's start with the basics.

What Is a Horizontal Grinder?

(Image Source: vermeer.com)

A horizontal grinder is a heavy-duty machine designed to turn organic materials like green waste into usable products like mulch , compost, or biomass fuel. It's widely used in land clearing, recycling centers, yard waste processing, and landfill operations. Depending on how the machine is set up, you can produce a coarse grind for bedding material or a finer mulch for landscaping.

Modern horizontal grinders come with advanced features like remote control, hydraulic clutches, Parker IQAN, telematics, Metal Detection System (MDS), etc. These tools help operators manage speed, rotation, and safety functions without standing right next to the machine.

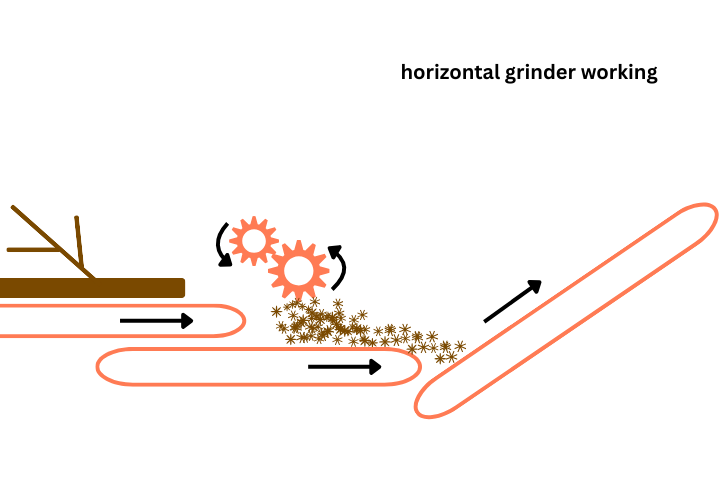

How Does a Horizontal Grinder Work?

At the core of a horizontal grinder is a grinding mill, which is a powerful rotor equipped with holders and teeth that shred the incoming material. As the material moves through the grinding chamber, the mill breaks it down into smaller pieces. A screen system then ensures the final product is uniform in size. Depending on the screen you use, you can produce different end materials.

The machine is powered by a high-horsepower diesel engine, commonly in the 600–1200 HP range. Today's engines often meet Tier IV emissions standards, which means they run cleaner without sacrificing performance.

A chain-driven feed roller and a conveyor system steadily feed material into the grinding rotor. This setup prevents jams and ensures a consistent, controlled flow. Once processed, the material is discharged and ready for use or further processing.

Pros & Cons of Horizontal Grinders

One of the main reasons operators choose horizontal grinders is safety. Because the feeding system is enclosed, there's less risk of material being thrown around. It is especially important in populated areas or busy worksites. These machines also handle long and bulky pieces of wood more effectively than other types of grinders.

Another key benefit is consistency. The feed system delivers the material into the grinding chamber with steady steps, and the screen system ensures a uniform particle size. As a result, the output is predictable and reliable for further use. In addition, modern horizontal grinders often feature reversible feed systems. If there's a risk of overloading the engine, this system can automatically back the material out.

However, horizontal grinders come with a high initial cost. Maintenance is also demanding, as parts like the cutting teeth, screens, and hydraulic systems need regular inspection and replacement.

Besides, horizontal grinders are less efficient with very bulky or irregularly shaped material, so pre-processing or sorting might be necessary. Another potential risk comes from contaminants such as metal, rocks, or bricks. Even small pieces can cause severe damage to the mill or rotor, so the Metal Detection System (MDS) is indispensable.

How to Choose the Right Horizontal Grinder?

Before purchasing a horizontal grinder, there are several key factors to consider in advance, such as your budget, your projects, and your long-term goals.

Don't stop at the sticker price. Fuel, maintenance, and wear parts will determine the real cost per hour. On industry forums, some operators estimate a 1,000-HP grinder can cost several hundred dollars per hour to run, once you add fuel, labor, and upkeep. One operator reported a 630-HP grinder burning 10–16 gallons of fuel per hour. Numbers like this can help you budget more realistically.

Think about where the grinder will work. Land-clearing jobs in rough terrain may call for a track-mounted machine that can move easily on site. If you're under tight deadlines, pay attention to production rates. Engine power, mill size, and feed/discharge design all play a role in how quickly material gets processed.

Check the specs carefully. Manufacturers usually rate machines by tons or cubic meters per hour. Torque is another key number. It shows how well the grinder can keep up with tough or oversized material without bogging down. Choosing a machine with a higher capacity than your average workload can prevent over-stress and extend its life.

Spending more upfront often pays off later. Machines that are fuel-efficient, operator-friendly, and built to last can save thousands over their lifespan. Features like reversible feed systems, automation, and quick-change screens may feel optional, but they improve productivity and lower labor costs.

How to Maintain a Horizontal Grinder?

Start with the feed rate. Feed too slowly, and productivity drops. Feed too fast, and the mill can jam or pass through unprocessed pieces. Use modern controls like Parker IQAN for automatic feed and reverse. These functions protect the engine and keep production steady. Skilled operators make a big difference. A well-trained loader operator reduces jams and unplanned stops.

Pick the right protection for your work, such as airbags, torque limiters, shear pins, or a Metal Detection System (MDS). Always assume contaminants (metal, rock, concrete) will appear and plan accordingly.

Short, regular checks keep the grinder running. Inspect the cutting head and teeth often. Operators commonly check the head every 4 hours of operation. Check screens, wear plates, sensors, and hydraulics daily. Clean sensors and control surfaces to avoid false trips. For clutches and hydraulics, follow manufacturer guidance; operators report changing clutch oil about every 350 hours on some setups. Small, frequent checks beat long, infrequent overhauls.

Stock the wear parts that stop you most often. Typical on-site inventory includes multiple screens, rotor teeth/tips, bolts, shear bars, filters, and floor plates. Operators commonly keep 100+ tips and bolts as spares. Also, keep clutch oil on hand.

Other Practical Lessons from Operators

- Keep the machine clean. Dirt and old grease cause sensor and clutch problems. Clean and lubricate protection systems so they work when needed.

- If your budget allows, choose machines with monitoring and adjustable controls. They save wear and cut risks.

- Finally, plan before you buy: evaluate your material source, market demand, transport costs, spare parts access, and maintenance capacity. Good planning and disciplined maintenance deliver the best uptime and the lowest lifetime cost.

Reliable Brands on the Market

Popular brands include: Peterson, Morbark, CBI, Vermeer, and Bandit.

Peterson offers a wide lineup of horizontal grinders, including tracked, wheeled, electric-stationary, and wheeled models, that let you choose what works best for your site and material types.

(Image Source: astecindustries.com)

Morbark 's Wood Hog series (models like the 6400X, 3400X, 3000X, etc.) is well regarded for handling large volumes of brush, yard waste, and woody feedstocks while turning them into saleable products efficiently.

(Image Source: morbark.com)

CBI 's grinders are built tough, with a rugged hog box, metal detection, shear pins, and features like quick-change tips and screens. They emphasize durability, high throughput, and lower downtime.

(Image Source: terex.com)

Vermeer builds tough grinders for jobs like land clearing, composting, and municipal waste. They offer different horsepower options like the HG6000 with up to 755 hp. Safety features such as duplex drums and debris deflectors also make their machines stand out.

(Image Source: vermeer.com)

Bandit's "Beast" series is known for versatility. The smaller Model 1425 works well for a lighter brush, while larger machines like the 4680XP push past 1,000 hp for heavy-duty grinding. They come in tow-behind or track options to fit different job sites.

(Image Source: banditchippers.com)

Horizontal Grinders vs. Tub Grinders

If you're weighing horizontal grinders against tub grinders , I've already broken this down in detail here . The short version: horizontal grinders give you more safety, control, and consistency, while tub grinders handle bulky or irregular material more easily. With that in mind, let's wrap up with a few final thoughts.

Final Thoughts

Horizontal grinders aren't small investments, but they can be game changers if your work involves a steady stream of wood, green waste, or other organic materials. They deliver consistency, safety, and efficiency when used and maintained properly. The key is to match the grinder to your operation, keep up with regular maintenance, and train your team members to run it right. Do that, and a horizontal grinder can serve you well for years.

*All of the above images are not intended for commercial use.