A stump grinder is an essential piece of equipment for removing tree stumps after cutting down a tree. It grinds stumps into small wood chips that can be used as mulch or easily disposed of. Whether you are a homeowner maintaining your yard or a landscaping contractor handling large projects, a stump grinder can make the job much easier and more efficient. Today, let's learn what a stump grinder is, how it works, and why it is important for stump removal.

(Image Source: Photo by Manuel Xavier on Unsplash.com)

What Is a Stump Grinder

A stump grinder is a powerful machine designed to remove the remaining stump after a tree has been cut down. It works by using a rotating cutting wheel equipped with carbide teeth to grind the wood into small chips. As the wheel spins at high speed, the operator moves it side to side and gradually lowers it to shave the stump layer by layer until it is below ground level. This process helps clear the area for replanting, landscaping, or construction.

(Image Source: vermeer.com)

The movement of the cutting wheel is usually controlled by hydraulic systems, allowing precise control of both depth and direction. Depending on the model, a stump grinder can be powered by either gasoline or diesel engines. These machines vary in size and design. Regardless of the type, operating a stump grinder requires attention to safety, as the machine's rotating blades and flying wood chips can be hazardous if mishandled.

Why Remove Stumps

Removing tree stumps is not only about appearance but also about maintaining a healthy and functional landscape. Old stumps left in the ground can decay over time, attracting mould, fungi, or insects that may spread to nearby plants. In addition, stumps can obstruct new landscaping projects such as patios, driveways, or garden paths. From a practical point of view, removing the stump also prevents new trees from sprouting and keeps the area clean and safe for future use.

Components of a Stump Grinder

A stump grinder has a simple working principle, but several key components make the process possible. At the core are three main systems: the engine, the drive system, and the cutting disc. Each plays a distinct role in converting engine power into the cutting action that turns a stump into chips.

Engine

The engine provides the machine's motive force. Smaller, walk-behind grinders typically use petrol engines similar to lawnmower motors; they are lighter and easier to maintain. Larger, commercial grinders usually run on diesel for greater durability and continuous-duty performance. The choice of engine affects fuel type, service needs, and how hard the machine can work day after day.

Drive system

Power from the engine reaches the cutter through a drive arrangement. Most grinders use heavy-duty belt drives that transfer torque while cushioning the engine from shock loads. Rubber belts are relatively inexpensive to replace and protect more costly components. On larger machines, hydraulic drive systems are common: the engine powers a pump, the pump runs a hydraulic motor, and the motor spins the cutter. This setup gives smooth, high-torque delivery suited to heavy-duty work.

Cutting disc

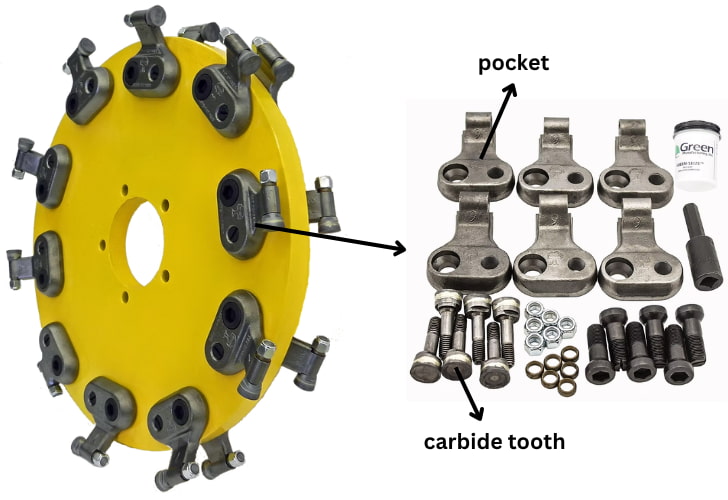

(Image Source: greenteeth.com)

The cutting wheel is the business end: a steel disc fitted with replaceable carbide teeth. The wheel spins at high speed and sweeps across the stump, chipping away wood one pass at a time. Wheels come in many sizes: small units have compact heads for tight gardens; large machines use wide wheels for fast removal of big stumps. Teeth wear with use and must be replaced periodically to keep cutting efficiency and to avoid extra strain on belts and the engine.

Types of Stump Grinders

1. Walk-behind stump grinders

Walk-behind grinders are the best option for homeowners and landscapers dealing with medium-sized stumps. They put the operator directly behind the machine and offer a balance of power and portability.

Tracked walk-behind grinders

(Image Source: vermeer.com)

These machines run on tracks rather than wheels. Tracks spread the machine's weight, so they are gentler on lawns and stable on uneven ground. Operators use onboard controls to guide the cutter with precision. Tracked units deliver more power and durability than wheeled walk-behinds, making them a better choice for larger stumps or rough sites. The drawback is transport: they are heavier and often need a trailer for moving between jobs.

Wheeled (handlebar) walk-behind grinders

(Image Source: baumalight.com)

Wheeled or handlebar grinders are compact and easy to maneuver. You guide them by hand using simple controls, so they work well in tight gardens and confined spaces. They are lighter, easy to load into a truck, and cost-effective for occasional use. Compared with tracked models, they offer less traction and slightly lower continuous-duty capability, but they are ideal for most residential jobs.

2. Attachment stump grinders

(Image Source: bluediamondattachments.com)

An attachment stump grinder is a cutter head designed to mount on existing equipment such as a skid steer or compact tracked loader. Instead of buying a standalone machine, you fit the grinder to the carrier and operate it with the vehicle's controls, using the same hydraulic and lift functions you already know. This option is cost-effective for owners who already have compatible equipment.

3. Riding stump grinders

(Image Source: vermeeraustralia.com.au)

Riding stump grinders are self-propelled, seat-mounted machines meant for larger clearing tasks. Instead of walking behind the unit, the operator drives the machine from stump to stump while using onboard controls. Where there are many stumps or when jobs require fast turnaround, riding stump grinders can be of great help.

4. Towable stump grinders

(Image Source: stumpcutters.com)

Towable (or tow-behind) stump grinders are heavy-duty units designed to be pulled by a truck or tractor. They feature more power and a larger cutter head than walk-behind or attachment types, so they remove big stumps more quickly and with fewer passes. This makes them well-suited to contractors or landowners managing wide properties or large-scale clearing jobs. Being towable also makes it straightforward to move the machine between remote or awkward sites, improving job-site efficiency when many stumps must be cleared.

5. Skid steer stump grinders

(Image Source: baumalight.com)

Skid steer stump grinders run on continuous tracks rather than wheels. The wide treads spread the machine's weight and provide strong traction, so they work well on soft, muddy, or easily damaged ground where wheels would sink or churn the turf. Operators can walk behind some tracked units or ride on others, depending on the model.

6. Remote-controlled stump grinders

(Image Source: stumpcutters.com)

Remote-controlled stump grinders are operated from a distance using a handheld transmitter. They were developed to improve operator safety by keeping the user away from the cutter and any hazardous ground conditions. These machines are mostly used on steep, unstable, or otherwise risky sites where standing next to the grinder would be unsafe.

How Does a Stump Grinder Work

A stump grinder removes tree stumps by using a high-speed rotating cutting wheel equipped with durable teeth, often made from tungsten carbide. As the wheel spins, the teeth chip away at the wood layer by layer, gradually reducing the stump until it is below ground level.

(Image Source: greenteeth.com)

The operator guides the cutting wheel across the entire surface of the stump, controlling depth and direction to ensure even removal. Smaller stumps can be cleared relatively quickly, while larger stumps require more passes.

Stump Grinder Teeth

(Image Source: greenteeth.com)

As mentioned earlier, stump grinder teeth are attached to the cutting wheel and do the actual cutting work. Their hardness and durability are essential for efficient grinding, which is why they're typically made from tungsten carbide, a material known for its strength and wear resistance. Each tooth has a carbide tip welded onto a steel body, creating a tough, long-lasting tool capable of cutting through even the hardest wood. Stump grinder teeth come in various shapes to fit different grinder models.

Conclusion

Stump grinders make tree removal more efficient by turning tough stumps into usable ground. With different types available, from compact walk-behind models to powerful remote-controlled machines, there's an option suited for every job size and terrain. Understanding how stump grinders work and what makes their cutting teeth so effective helps ensure safer, faster, and cleaner results, whether you're a professional landscaper or a homeowner handling occasional yard work.

*All of the above images are not intended for commercial use.