When roads start breaking down or get filled with potholes, it's every driver's worst nightmare. Full reconstruction isn't always necessary or practical. In many cases, asphalt milling (also called pavement milling, road milling, or cold milling) is a smarter, more cost-effective solution. Instead of tearing everything out, this method removes just the top layer of the old pavement. This makes way for a smooth new surface.

(Image Source: Photo by Jens Aber on Unsplash.com)

And the best part? The removed asphalt will be recycled and mixed with other materials and reused in future projects. That makes milling not only efficient but also an eco-friendly choice.

So, what exactly is asphalt milling? Why is it widely preferred over other repair methods? What kind of machines are used in cold milling? And what does the process actually look like step by step? Read on to explore the answers.

What is Asphalt Milling?

Asphalt milling is the process of removing the top layer of an existing paved surface. Imagine a giant grinder carefully shaving off the old asphalt, usually at a depth of about 2 inches, though the cut can be shallower or much deeper depending on the condition of the road. Instead of ripping out the entire road, milling targets just the surface that's cracked, uneven, or worn down. Specialized milling machines grind up the old asphalt, leaving behind a smooth, level base. That base can then be repaved with a fresh layer of asphalt.

Applications & Purposes of Asphalt Milling

The main goal of asphalt milling is simple: remove the worn-out surface layer so that a fresh overlay can bond securely. This process tackles common road problems such as cracks, rutting, surface roughness, fire or accident damage, and even issues like bleeding or raveling that make pavement unsafe or uncomfortable to drive on.

(Image Source: Photo by Zoshua Colah on Unsplash.com)

But asphalt milling does more than just “make the road smooth.” It's also a precise tool for height and surface control. With milling, contractors can:

- Ensure the right elevations and clearances around curbs, manholes, catch basins, shoulders, and guardrails.

- Adjust slope, camber, and grade to improve drainage and prevent water from pooling.

- Maintain overhead clearance in areas where even small thickness changes matter, like tunnels and under bridges.

And it's not limited to highways. You'll find asphalt milling used on various roads (from arterials to neighborhood streets), parking lots & driveways, sidewalks & paths, and more.

The RAP (Reclaimed Asphalt Pavement)

When asphalt pavement is removed, it doesn't just get hauled away as waste. It's reused as RAP (Reclaimed Asphalt Pavement). This material is actually one of the most valuable resources in modern road construction. By blending RAP with fresh aggregate and binder (or a recycling agent), contractors can cut project costs while reducing the environmental footprint of resurfacing.

(Image Source: asphalticons.com)

In most cases, RAP goes right back into roadway structures through hot or cold recycling. It can also be repurposed as aggregate for base or sub-base layers, adding stability to the road foundation. While you won't see RAP as often in high-traffic urban areas, it still has plenty of uses elsewhere, like granular base, stabilized fill, or even embankment material.

The Key Equipment Used in Asphalt Milling

(Image Source: wirtgen-group.com)

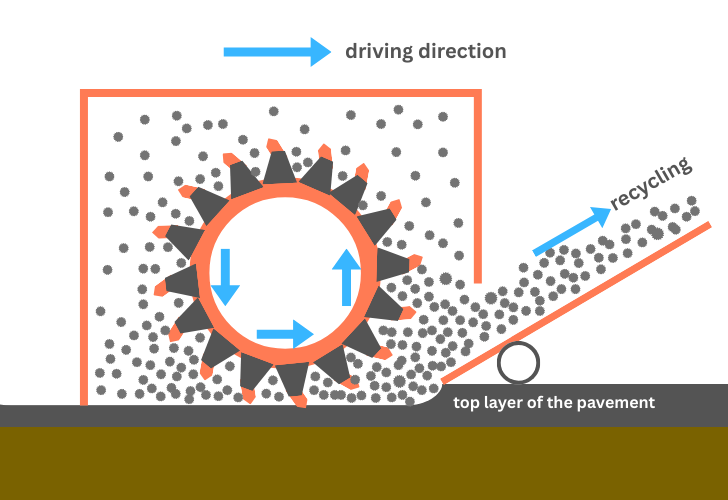

Asphalt milling is carried out with specialized equipment known as cold planers , or more commonly, cold milling machines. At the heart of the machine is a large rotating drum. Rows of tool holders, holding carbide cutters or road milling teeth , are mounted on the drum. Carbide cutters are replaceable, since they wear down at different rates depending on the hardness of the pavement being milled.

(Image Source: wirtgen-group.com)

As the drum spins, these teeth cut into the pavement and push the material toward the center. Then a conveyor system carries the removed material away for recycling. The picture above shows that a dump truck is working in front of a cold planer, and the cold planer is continuously conveying the removed material (RAP) to the truck.

Most machines use an up-cut design, where the drum rotates opposite to the machine's travel direction for a smoother finish. The spacing of the cutters determines the texture of the surface. Tight spacing creates a finer finish, known as micro milling.

Modern cold planers also come equipped with automatic depth and slope controls, often using lasers or string-line systems, allowing operators to achieve highly accurate milling results, within about ±5 mm of the target depth.

Asphalt Milling Process

The asphalt milling process is a step-by-step way to remove the top layer of a road and get it ready for a fresh surface:

- Assess the pavement: Start by checking the asphalt's condition. Milling works best when the top layer is worn or damaged, but the sub-base is still solid. Look for cracks, raveling, or other surface issues to determine how much material needs to be removed.

- Prepare the area: Measure the milling zone, mark start and end points, and identify hard obstacles like manholes or embedded structures. This helps the machine work safely and efficiently.

- Mill the surface: Using a milling machine (cold planer), grind off the top layer to the right depth, usually around 2 inches, depending on the damage. Operators can fine-tune the depth to remove just enough for a smooth, level base.

- Collect the millings: The removed asphalt (RAP) is loaded into dump trucks. The RAP can be reused in new asphalt mixes or other construction projects.

- Clean the surface: Sweep or wash away dust, loose millings, and debris so the new asphalt adheres properly.

- Pave the new surface: Finally, lay fresh asphalt over the prepared base.

What Are the Benefits of Asphalt Milling?

Going with asphalt milling instead of other repair methods comes with a lot of benefits. It's not just about getting the road fixed faster. It's about saving money, improving safety, and making the process more sustainable.

(Image Source: Photo by Max on Unsplash.com)

Cost-Effective

Milling removes only the damaged top layer, keeping the solid sub-base in place. That means less work, fewer materials, and a much smaller cost compared to full reconstruction.

Even better, the old asphalt isn't wasted. Those millings (RAP) get recycled into new mixes, cutting down on raw material costs. Whether you're a city planner or a homeowner, the savings add up. And because milling leaves behind a smoother, more durable surface, you'll also spend less on future repairs.

Environmentally Friendly

Instead of sending old pavement to a landfill, milling recycles it right back into the system. RAP can be reused in hot or cold mixes, or even as a base layer.

This reduces the demand for new aggregate mining and oil refining, which means lower energy use and fewer emissions. Plus, the process itself is clean, no burning, no smoke, and less dust thanks to water controls.

Safer Surfaces

Milling takes care of ruts, cracks, bumps, and slick spots, giving drivers better skid resistance and reducing hazards.

For pedestrians, it removes sharp edges and uneven surfaces that can lead to slips or trips. In short, it makes the road safer for everyone.

Quick & Convenient

Full-depth reconstruction takes time. Milling, on the other hand, is fast. In many cases, traffic can even shift onto a freshly milled lane while crews keep working on the other. That means fewer lane closures and shorter project timelines.

And unlike traditional hot mix asphalt that may take up to 72 hours to cure, compacted millings usually set in about 24 hours.

Durable & Versatile

When compacted, asphalt millings bond tightly thanks to the bitumen already in them. The result? A stable, weather-resistant surface.

They work just about anywhere, including roads, parking lots, driveways, sidewalks, and even as base or fill material in other projects. With micro milling techniques, you can even achieve a fine, smooth finish when needed.

What Is Micro Milling?

While asphalt milling is all about removing worn-out pavement efficiently, micro milling takes it one step further, focusing on precision and surface quality. It uses the same type of machine as standard milling, but with one big upgrade: the drum carries three to four times more cutting teeth. More teeth mean it can grind pavement into much finer particles and leave behind a smoother, more even surface.

Unlike standard milling, which can go several inches deep, micro milling usually works best at shallow depths, about two inches or less. That makes it perfect for projects where the goal is to improve ride quality, adjust grade or elevation, or prep the road for a thin overlay.

The results go beyond looks. A micro-milled surface is quieter, safer, and more skid-resistant. It also gives the next asphalt layer a perfect base to bond to. And in some cases, the finish is so good that micro milling alone can serve as the final surface treatment, no extra asphalt needed.

*All of the above images are not intended for commercial use.