From machining hardened steel to resisting abrasion in mining and construction tools, cemented carbide has become a go-to solution when both durability and reliability matter. It's not just hard; it's engineered to endure.

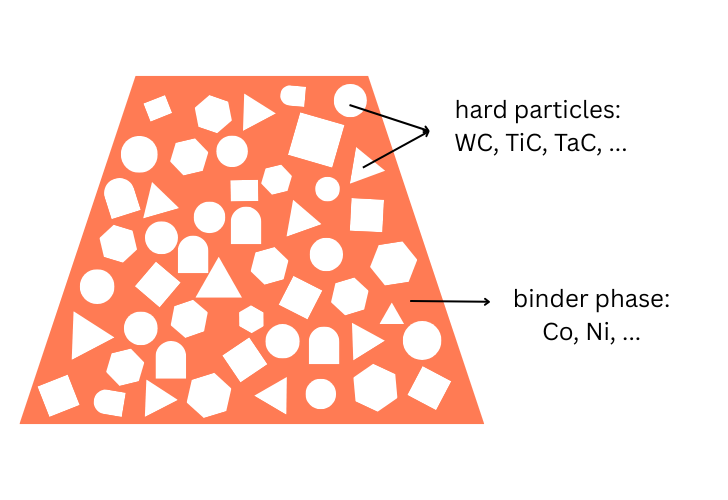

At its core, cemented carbide is a tough, high-performance composite made by combining hard carbide particles, typically tungsten carbide (WC) , with a metallic binder like cobalt (Co) or nickel (Ni). This material strikes a remarkable balance between two often opposing features: extreme hardness and structural toughness.

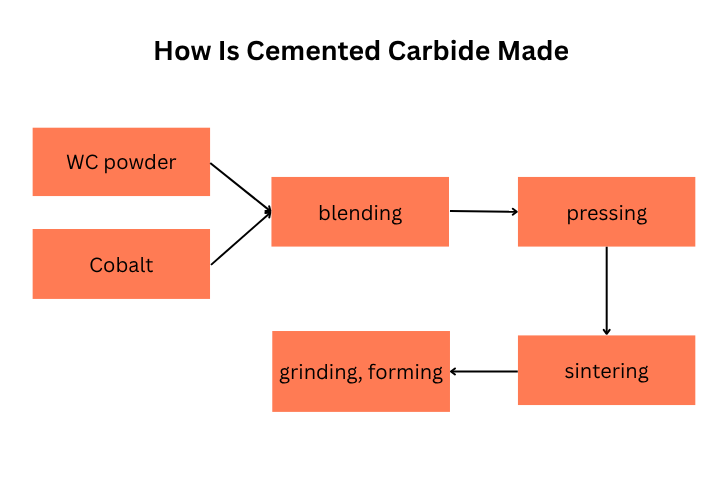

How Is Cemented Carbide Made?

Cemented carbide is manufactured through powder metallurgy technology. Finely ground carbide powders are blended with a small percentage of binder metal (usually 3%-30%) in a ball mill. It takes about 8 to 24 hours to ensure uniform particle size. The mixture is then pressed into shape and is ready for sintering.

Sintering is the most crucial process of manufacturing cemented carbide. There are three most commonly used sintering techniques: Vacuum Sintering, Hot Isostatic Pressing (HIP), and Spark Plasma Sintering (SPS). During sintering, the particles fuse to form a dense, solid structure with minimal porosity and excellent mechanical integrity.

Types of Cemented Carbide

The most widely used type is tungsten carbide with cobalt (WC-Co), known for its outstanding wear resistance and hot hardness, qualities that make it ideal for cutting tools, dies, and wear parts. Other carbides like titanium carbide (TiC) , tantalum carbide (TaC), and niobium carbide (NbC) may also be added to fine-tune performance for specific tasks. Similarly, the binder phase can be tailored using elements such as nickel, iron, or chromium to change corrosion resistance or magnetic properties.

Properties of Cemented Carbide

Cemented carbide stands out for its unique combination of hardness, toughness, and strength, traits that are rarely found together in a single material. Its exceptional wear resistance makes it the first choice in demanding applications where conventional materials would quickly fail.

One of its most notable properties is hardness, typically rated between 80 and 94 HRA. Thanks to the ultra-hard carbide particles, cemented carbide can resist abrasive wear far better than most metals or ceramics. When fine or ultra-fine WC grains are used, hardness and strength are further enhanced, making it ideal for cutting tools and precision components.

Despite being extremely hard, cemented carbide also maintains good strength and toughness. Its transverse rupture strength can exceed 2 GPa, significantly outperforming ceramics in resistance to sudden fracture or impact. This balance between rigidity and durability is a key reason why cemented carbide is trusted in critical tooling and engineering applications.

Other important mechanical properties include:

- Compressive strength: essential for withstanding high-pressure loads without failure

- Impact strength: supports use in applications involving shock or vibration

- Young's modulus: three times greater than that of steel, offering high stiffness

- Specific gravity: roughly double that of iron, reflecting its dense structure

From a performance standpoint, cemented carbide also excels in thermal stability and corrosion resistance, especially when using binders like nickel. These features allow it to maintain integrity under extreme temperatures and in chemically aggressive environments. Its tribological properties, resistance to friction and surface wear, are another reason for its long tool life in high-speed machining or forming operations.

Applications of Cemented Carbide

Cemented carbide is engineered for extreme environments, places where high loads, intense friction, and elevated temperatures would quickly destroy conventional materials. Its unique balance of hardness and toughness makes it an ideal solution in situations where both durability and reliability are required.

One of the most common applications is in cutting tools, including drills, end mills, carbide inserts, and saw blades. These tools often operate at high speeds and temperatures, especially when machining hard metals like stainless steel or cast iron. Cemented carbide not only withstands the heat and stress, but also maintains a sharp cutting edge for much longer than traditional HSS.

Beyond cutting, cemented carbide is widely used in wear parts and tooling components & carbide blanks , including:

- Punches and dies in metal forming

- Nozzles and valve seats in fluid handling systems

- Mining and construction tools, such as drill bits, road milling teeth, and crushing equipment

- Oil and gas components exposed to high-pressure, corrosive conditions

- Woodworking and industrial slitting blades