Tungsten carbide, more precisely known as cemented carbide, is a composite material made of hard carbide phases such as WC (tungsten carbide), TiC (titanium carbide), or TaC (tantalum carbide), bonded together with metallic binders like cobalt (Co) or nickel (Ni). It is widely recognized for its outstanding hardness, along with excellent wear resistance, heat resistance, and corrosion resistance. Among all these properties, the hardness of tungsten carbide stands out the most, especially because it can remain stable even under high temperatures ranging from 500 °C to 1000 °C.

Thanks to these advantages, cemented carbide is commonly used as a raw material for producing cutting tools and blades, molds and dies, as well as various wear parts. In practice, many of these tools are made from carbide blanks and preforms , which are further ground or shaped for specific applications.

(Image Source: Photo by Michael Kauer from Pixabay.com)

So, what exactly does carbide hardness mean? What factors influence the hardness of tungsten carbide? And is higher hardness always the best choice? Let's go through these questions one by one.

What Is the Hardness of Tungsten Carbide?

In simple terms, hardness describes a material's ability to resist permanent surface deformation when an external force is applied. For tungsten carbide, hardness refers to its resistance to indentation caused by other hard materials under load. In practice, the hardness of tungsten carbide is measured using different standardized testing methods. As a result, carbide hardness is usually expressed in several commonly used scales rather than a single value.

- On the Mohs scale, tungsten carbide typically falls in the range of 9.0 to 9.5.

- Using the Vickers hardness test, carbide generally shows values from around 700 HV30 up to 2200 HV30.

- On the Rockwell A scale (HRA), the hardness of tungsten carbide usually ranges from 80 to 94 HRA.

Key Factors Affecting the Hardness of Tungsten Carbide

You may wonder why tungsten carbide is so hard. In fact, its hardness is determined by several factors.

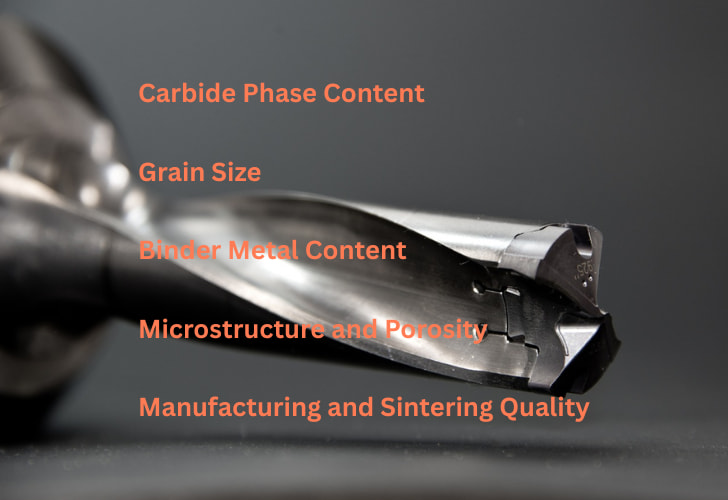

(Image Source: Photo by Michael Schwarzenberger from Pixabay.com)

Carbide Phase Content

Tungsten carbide particles form the main hard phase of cemented carbide. In general, a higher proportion of tungsten carbide leads to higher hardness, because these particles carry most of the load and resist surface deformation.

Grain Size

Grain size plays a crucial role in carbide hardness. Finer tungsten carbide grains result in a denser and more uniform structure, which increases hardness and improves wear resistance. As the grain size becomes smaller, deformation becomes more difficult under external force.

Binder Metal Content

Metal binders such as cobalt are necessary to hold carbide grains together. Increasing binder content improves toughness, but it usually comes at the cost of reduced hardness. This is why finding the right balance between hardness and toughness is essential for different applications.

Microstructure and Porosity

A uniform microstructure with low porosity contributes to higher hardness. Defects such as pores or uneven grain distribution weaken the material and reduce its resistance to indentation.

Manufacturing and Sintering Quality

The hardness of tungsten carbide is also influenced by the manufacturing process. Pressing and sintering conditions affect grain bonding and porosity. Proper high-temperature sintering helps form a compact structure, which improves both hardness and overall structural strength.

Different Carbide Hardness Levels for Different Applications

As we mentioned earlier, carbide hardness is closely related to tungsten carbide grain size and binder (cobalt) content. Together, these factors determine whether a carbide grade is more suitable for cutting, forming, or impact-resistant applications.

High Hardness: Fine Grain with Low Cobalt Content

Carbide grades with fine grains and low cobalt content (usually below 10%) offer very high hardness and wear resistance. These grades are well-suited for applications where sharp cutting edges and dimensional accuracy are required, such as precision cutting tools.

Medium Hardness: Medium Grain with Moderate Cobalt Content

With medium grain size and a cobalt content of around 10–15%, hardness is slightly lower, while toughness is improved. This combination works well for forming tools like stamping dies and drawing dies.

Lower Hardness: Coarse Grain and High Cobalt Content

Carbide materials with coarse grains and higher cobalt content (above 20%) have lower hardness but much better impact resistance. These properties are essential for demanding environments, such as mining and construction tools, where components must withstand heavy loads and repeated impact.

Hardness Is Not the Only Selection Criterion

Although hardness is an important reference, it should never be the only factor used for material selection. Toughness, strength, and actual working conditions all matter. This is exactly why carbide grades exist. To learn more about tungsten carbide grades, please read our article on tungsten carbide grades .

Does Higher Carbide Hardness Always Mean Better Performance?

A higher hardness value does not necessarily lead to better performance in real applications. One reason is that standard hardness tests cannot fully reflect how carbide tools are used in practice.

The hardness of tungsten carbide is commonly measured using Rockwell or similar indentation-based tests, where force is applied slowly through a diamond indenter. While these tests are standardized, they represent simplified conditions that are very different from real working environments.

As a result, carbide grades with lower measured hardness might outperform grades with higher hardness in actual wear situations. Official hardness values should therefore be seen as general references rather than precise indicators of tool life or service performance.

In practice, when people talk about carbide hardness, what they are really concerned about is performance, longer service life, fewer failures, and better suitability for specific working conditions. This is why carbide selection has always involved a trade-off between hardness for wear resistance and toughness to prevent breakage.

(Image Source: Photo by Nile from Pixabay.com)

Conclusion

The hardness of tungsten carbide is an important property that reflects its resistance to surface deformation and wear, but it should never be considered on its own. As discussed above, carbide hardness is influenced by factors such as carbide content and grain size, which together determine how the material performs in different applications.

More importantly, higher hardness does not guarantee better results. In real-world use, the best performance comes from selecting the right carbide grade that matches the actual working conditions, rather than simply choosing the hardest material available.