Most forestry mulcher owners often wonder: when should I replace my mulcher teeth?

It's not a simple yes-or-no question. Instead, several factors come into play. For instance, did you purchase high-quality original teeth from reliable manufacturers? Do you operate the mulcher according to the user manual? Has your machine struck hard materials, such as rocks or metal?

(Image Source: Photo by Gorrin Bel on Unsplash.com)

All these factors affect how often the teeth need to be changed. So, let's dive right in and figure out what really tells you it's time for a replacement.

When to Replace Mulcher Teeth?

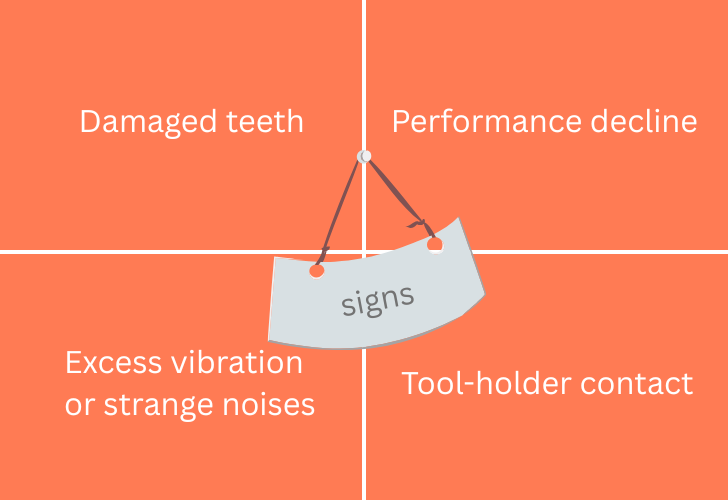

Here is a short, practical answer: replace the teeth when they stop cutting efficiently or when inspection shows damage that can't be safely or effectively fixed. Below, I break that down into clear, actionable signs you can use on the job.

1. Daily visual checks: the fastest way to catch problems

Make a habit of checking the teeth every shift. A quick daily glance will reveal chips, cracks, missing pieces, or edges that have become rounded. Those are the first and most reliable indicators that a tooth is losing cutting ability. Small chips can sometimes be managed; cracks, fractured, or missing teeth mean replace immediately.

2. Performance decline: watch what the machine tells you

If your mulcher is noticeably slower, needs more passes to do the same job, or you find yourself pushing harder to get the job done, that's a performance alarm. Worn teeth blunt the cutting action and increase fuel and time costs. Replace before the situation worsens.

3. Excess vibration or strange noises: balance and safety signs

New or evenly worn teeth run smoothly. If the head vibrates excessively or the unit makes unusual sounds, suspect uneven wear, a cracked tooth, or a missing tooth. Excess vibration not only reduces cutting quality but can damage the rotor, tool holders, and bearings.

4. Tool-holder contact: the critical red flag

The single most serious sign: the tooth is worn so far back that the tool-holder starts contacting the material. At that point, you risk damage to the holder and rotor. Replace immediately. Daily inspections should include a check for this condition.

Why Mulcher Teeth Wear Out & Lifespan Ranges

1. What really wears out mulcher teeth

Several factors determine how fast a set of mulcher teeth will wear:

Tooth design

Carbide-tipped teeth generally last much longer than steel or planer-style teeth, because carbide resists abrasion and doesn't require frequent sharpening.

On The Forestry Forum, a user (VT_Forestry) reported that their carbide hammer-style teeth ran "upwards of 400–500 hours before they need to be replaced", as long as they didn't hit concrete, rebar, or engine blocks. Another operator (redprospector) mentioned getting 600 hours from double-carbide tools on one head, compared to only 300 hours on another setup, showing how tooth design and machine type directly affect lifespan. (Source: The Forestry Forum)

Operating environment

Mulching clean, soft ground is very different from working on abrasive soil or rocky terrain. Sand, gravel, and hidden rocks accelerate tooth wear by constantly grinding down the cutting edges. In abrasive conditions, users often have to rotate or sharpen teeth after just 50 hours, while in ideal conditions, they may last several hundred hours.

Tooth Quality

Genuine teeth from the original manufacturer are made with precisely engineered alloys and heat-treatment processes designed for long-term durability. These material formulas are proprietary, something aftermarket or unverified suppliers simply don't have access to. As a result, these "look-alike" teeth may appear identical on the outside but often contain lower-grade materials that wear faster, chip more easily, and can even damage the holder or rotor.

Material being processed

Hardwoods, dense stumps, and old root systems put much greater stress on the teeth than brush or softwood. Data from multiple forestry equipment sources indicate that when processing hardwoods or stumps, teeth may need replacement after 30–50 hours, whereas working mainly in brushy or soft terrain can last 50–100 hours before major wear becomes visible.

Operator habits and maintenance

Operator skill makes a measurable difference. The same machine, in the same soil, can produce different results depending on how aggressively it's run. A careful operator who avoids digging into the dirt layer and sharpens or rotates the teeth on schedule can nearly double their usable life compared to a careless one. Routine cleaning and greasing also prevent premature damage from vibration and buildup.

2. Typical lifespan ranges

The information below summarizes data from manufacturers and real-world users:

- Carbide hammer-style teeth (clean ground): 400–500 h (Up to 600 h)

- Planer-style or steel teeth (abrasive soil): 50–100 h

- Hardwoods, stumps, or rocky terrain: 30–50 h

- General forestry mulching (average mix): 200–500 h

Remember: Keeping a basic service log helps you stay ahead of unexpected failures. Record the hours worked, material type, and date of each replacement or sharpening.

Selection Tips for Mulcher Teeth

Here are some useful tips for selecting the right mulcher teeth:

1. Match the Tooth to Your Material

- Hardwoods, stumps, roots: Go for teeth built to withstand tough, dense material. Carbide teeth are ideal here. They stay sharp longer and resist abrasion.

- Softwood, brush, lighter vegetation: Cubit knife or lighter teeth work well. They cut cleanly, are less expensive, and are sufficient for everyday lighter tasks.

2. Check Compatibility with Your Machine

- Always confirm the specs from your manufacturer. Teeth not designed for your mulcher model can cause poor fit, extra wear, or even damage to the rotor and tool holder.

- Consider rotor type. Certain machines require teeth that match the specific lacing pattern.

3. Avoid "Will-Fit" Teeth

- These may seem cheaper initially, but can compromise performance, wear out quickly, and damage tool holders.

- They may void the machine warranty and create costly downtime. Genuine teeth are engineered for durability, proper fit, and safe operation.

Conclusion

The service life of each mulcher tooth is limited. Knowing when to replace your mulcher teeth is essential for keeping your machine efficient, safe, and productive. Watch for signs like dull edges, cracks, excessive vibration, or tool-holder contact, and plan replacements based on the material you're processing and hours of use.

*All of the above images are not intended for commercial use.