Carbide blanks, also known as tungsten carbide blanks or cemented carbide blanks, serve as the foundation for manufacturing cutting tools and wear parts. For procurement professionals, sourcing carbide blanks can be a bit of a puzzle. When you request quotes from different global suppliers, you might notice a significant price gap. The price of carbide blanks depends on multiple factors. Understanding these variables is the key to finding the best value for your specific application.

Today, we will break down the main factors that influence carbide blank prices to help you make more informed purchasing decisions. Let's dive in!

Raw Material Costs

Cemented carbide blanks are mainly made of tungsten carbide (WC) and a metallic binder. In most grades, tungsten usually accounts for about 70% to 97% of the total composition. For this reason, the price of tungsten powder is the most direct factor behind the global carbide blank price.

Over the past year, tungsten prices have increased significantly. As of January 21, 2026, tungsten powder was quoted at RMB 1,240 per kilogram, up 14.8% compared with the beginning of the year. At the same time, tungsten carbide powder was reported at RMB 1,200 per kilogram, showing a 15.4% increase. As a result, this rise in upstream material costs is directly passed on to tungsten carbide blanks and then further affects downstream cutting tools and wear parts.

Some products with very low carbide content may be less affected by this price increase. However, carbide blanks are clearly not in this category.

Apart from tungsten, cobalt powder is used as the main binder, typically accounting for about 5% to 15% of the composition. Cobalt is mainly sourced from the Democratic Republic of the Congo. Political instability in the region, together with increasing ESG (Environmental, Social, and Governance) requirements in global supply chains, adds more uncertainty to cobalt supply and pricing. For high-cobalt grades designed for better toughness, this cost impact is even more obvious.

In addition, for special grades used in extreme working conditions, such as high temperature or strong corrosion, small amounts of elements like tantalum (Ta), niobium (Nb), and titanium (Ti) are added. Although the usage is limited, these materials are very expensive. For this reason, premium and specialty cemented carbide blanks usually have much higher prices than standard grades.

Manufacturing Process Complexity

For standard carbide blanks, typical tolerances are around ±0.05 mm to ±0.2 mm. For precision blanks, the tolerance requirement can be tightened to ±0.02 mm or even stricter. To achieve this level of accuracy, more precise pressing dies and tighter control during sintering are required.

Apart from tolerance, part shape also plays an important role. Simple shapes, such as rectangular or cylindrical blanks, are much easier and cheaper to produce. In contrast, complex and irregular shapes require customized pressing molds. These custom molds are expensive, and in many cases, mold costs can reach tens of thousands or even hundreds of thousands of RMB.

Different sintering processes also lead to significant cost differences. Standard vacuum sintering is widely used and relatively cost-effective. However, for high-end cemented carbide blanks that require ultra-high density and extremely low porosity, HIP (Hot Isostatic Pressing) is often applied. HIP equipment is expensive and energy-intensive. Compared with standard vacuum sintering, this process can increase production costs by 50% to 100%. In addition, gradient carbide grades, where the surface and core have different compositions, require special sintering control. This makes the process more complicated and further increases the final price.

Grain size is another important factor. Ultra-fine grain (grain size below 0.5 μm) and nano-grain cemented carbides require stricter raw material control and much tighter sintering parameters. The production process is more difficult, and the yield rate is usually lower. So, the prices of ultra-fine and nano-grain carbide blanks are commonly 2 to 3 times higher than those of standard grain grades.

Order Volume & Customization

For customers with annual orders reaching several tons, the unit price of carbide blanks can be as low as 50% to 60% of the price paid by small-volume buyers. In these cases, suppliers still need to cover mold costs, production line adjustments, and additional management costs. As a result, the unit price can be double, or even higher, compared with large-volume orders.

In addition, common sizes, such as standard 330mm round rods , have strong and stable demand. The molds can be reused, and production processes are highly standardized. Therefore, these standard tungsten carbide blanks are usually priced much lower than customized sizes.

Technology & Quality Standards

Suppliers certified to standards such as ISO 9001, AS9100 for aerospace, and IATF 16949 for the automotive industry often charge 10% to 20% higher prices compared with non-certified suppliers. For applications in sensitive industries such as defense, nuclear power, and aerospace, these certifications are basic entry requirements. Without them, suppliers are simply not qualified to participate.

In addition, some suppliers provide quality inspection reports and full raw material traceability records. These quality assurance measures increase production and management costs. However, for critical applications, they are essential rather than optional.

According to a report, a mining company once used low-cost cutting picks with poor-quality carbide and experienced frequent breakage. This led to unplanned downtime and production losses of several million US dollars. After that, the company decided to work only with fully certified brand suppliers, even when prices were 30% higher. For this reason, in many industrial applications, buyers are willing to pay more for certified and well-documented cemented carbide blanks, because the overall risk and total cost are much lower.

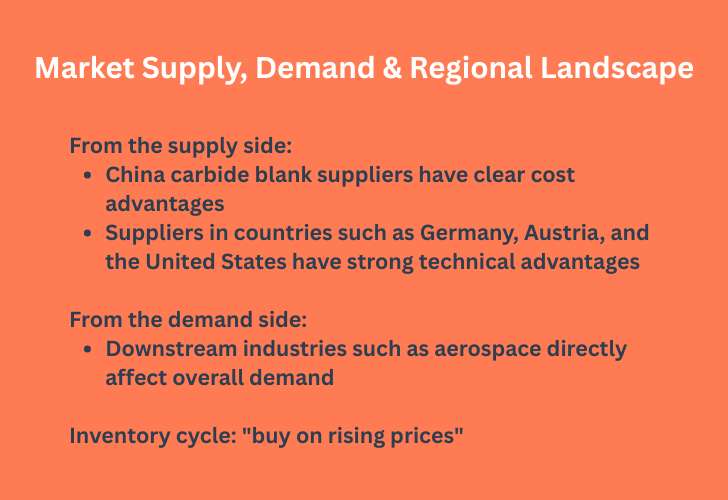

Market Supply, Demand & Regional Landscape

From the supply side, China accounts for more than 70% of global cemented carbide production capacity and has clear cost advantages in several aspects. Firstly, China controls over 80% of the world's tungsten resources, which gives it a natural advantage in raw material sourcing. Secondly, industrial clusters such as Zhuzhou in Hunan Province and Zigong in Sichuan Province have formed complete supply chains, covering everything from tungsten mining and powder production to finished cemented carbide blanks. Finally, although labor costs in China have increased in recent years, they are still much lower than in Europe and the United States. Due to these reasons, for standard carbide blanks, Chinese suppliers often quote prices that are 30% to 50% lower than those from Europe or North America.

Suppliers in countries such as Germany, Austria, and the United States usually have higher production costs. However, they have strong technical advantages in ultra-precision and aerospace-grade tungsten carbide blanks. For these high-end products, price premiums of 2 to 3 times are common. Customers are paying for tighter tolerances, more advanced processes, and long-established brand reputation. International first-tier brands such as Sandvik, Kennametal , and Ceratizit can often charge 20% to 40% more than lesser-known manufacturers, even for relatively standard specifications.

From the demand side, downstream industries such as aerospace, automotive manufacturing, mining, and oil & gas drilling directly affect overall demand for carbide blanks . A typical example can be seen during the commodity boom in 2020–2021. Coal prices in China rose from around RMB 400–500 per ton to peaks above RMB 2,000 per ton. Coal mines increased production, which led to a surge in demand for carbide cutting picks. As a result, demand for blanks increased sharply, pushing up prices. For some specifications, supply even became tight, and customers had to wait in line for delivery.

As for the inventory cycle, market expectations also influence short-term pricing. When raw material prices are expected to rise, downstream buyers tend to place orders in advance and build inventory. This short-term stocking behavior pushes up demand and supports higher prices, creating a typical "buy on rising prices" mindset. On the other hand, when the market expects prices to fall, buyers often delay purchases and take a wait-and-see approach. This weakens demand and can further pressure the price of carbide blanks.

Macroeconomic & Trade Environment

The sintering of cemented carbide blanks requires very high energy consumption. It is a major part of the total production cost. A typical example is the European energy crisis in 2022. Due to the Russia-Ukraine conflict, natural gas supply in Europe became tight. Natural gas prices in Europe once surged to 3 to 4 times the level in China, and electricity prices also increased significantly. As a result, many European carbide manufacturers were forced to raise their product prices by around 15% to 25%. Some companies even had to temporarily cut production. In comparison, energy prices in China remained relatively stable. During periods of global energy volatility, this has become an important cost advantage for Chinese-made carbide blanks.

Apart from energy, tariffs and trade barriers also directly affect procurement costs. In some cases, regional trade tensions lead to additional duties on specific products, which are eventually reflected in higher landed costs for buyers.

Practical Tips for Global Buyers

After understanding the factors above, we believe that buyers can make smarter and more informed purchasing decisions.

Clarify Your Priority: Performance or Cost

First of all, ask yourself a simple question: Is ultimate performance the top priority, or is the best possible cost the main goal? This decision will largely determine where you should source your carbide blanks and what type of carbide blank suppliers to focus on.

Provide Clear and Complete Specifications

A detailed technical drawing is far more effective than a general description. Clear information on material grade, dimensions, tolerances, and performance requirements helps suppliers provide more accurate and comparable quotations.

Total Cost of Ownership

In some cases, a blank with a slightly higher unit price but more stable quality and longer service life can result in a lower total tool cost. When evaluating tungsten carbide blanks, it is important to consider quality consistency, tool life, and process stability, rather than focusing only on the initial purchase price.

Use Professional Platforms to Select Suppliers

As MechCarbide provides, using detailed supplier information makes it easier to compare different manufacturers based on technical strengths, production capabilities, and market positioning. A carbide blank manufacturer that can communicate transparently about its process, quality system, and cost structure is usually a more reliable long-term partner.