When manufacturing tungsten carbide products with complex geometries, efficiency and cost are always the biggest challenges. Fully machining a finished part from a standard blank is often time-consuming, material-wasting, and expensive. This is where carbide preforms come into play. Instead of starting from a simple round or rectangular blank, manufacturers can work with a near-net shape carbide form that already resembles the final part.

However, if you search online, you will find that there is no strict or unified definition of carbide preforms. In different contexts, they may also be referred to as green compacts, pressed blanks, or pre-sintered parts. The boundaries between carbide blanks and preforms are often blurred, which can be confusing, especially for buyers sourcing carbide products globally .

That's why we are going to break it down clearly. We will explain what carbide preforms really are, why they are needed, how they differ from conventional carbide blanks, and where they are commonly used.

Without further ado, let's get started!

What Are Carbide Preforms?

In general, carbide preforms are complex-shaped, unsintered carbide components formed at the powder stage. More specifically, tungsten carbide preforms are made by mixing tungsten carbide powder with binders such as cobalt, then pressing the mixture into shape using precision molds before sintering. At this stage, the product is in a so-called green state. It has a certain level of strength, similar to chalk or dense clay, but it is far from reaching its final hardness.

The key feature of carbide preforms lies in their geometry. Their shape is already very close to the final part, often described as near-net shape carbide. After purchasing the preform, customers mainly need to sinter, and then grind the product, to produce the finished carbide product.

Carbide Preforms vs. Carbide Blanks

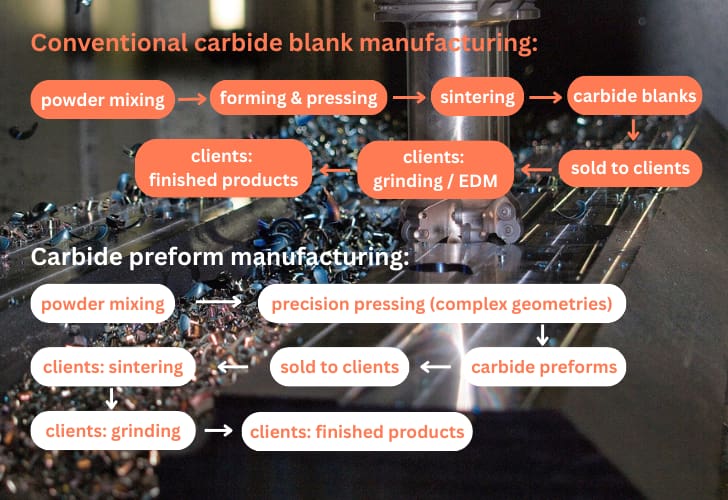

Carbide blanks and carbide preforms are often mentioned together, but they are fundamentally different in the manufacturing stage and application.

(Image Source: Photo by gefrorene_wand from Pixabay.com)

Generally speaking, carbide blanks refer to products that have already been sintered. At this point, the material is hard and brittle. Any further processing can only be done through subtractive methods, such as grinding or EDM. Shape modification is limited, and material removal is unavoidable.

In contrast, tungsten carbide preforms are unsintered products. They are formed before sintering, which means customers retain control over the final sintering process and the dimensional shrinkage that comes with it. This stage is critical, especially for parts with tight tolerances or complex geometries.

Why Are Carbide Preforms Needed?

The primary reason for using carbide preforms is shape complexity.

Many tungsten carbide components feature internal cavities, irregular holes, thin walls, stepped structures, or complex surfaces. Producing these geometries after sintering, when the material is fully hard, relies on grinding or EDM. This is extremely time-consuming, costly, and in some cases, simply impractical. By contrast, tungsten carbide preforms allow these complex shapes to be formed directly at the powder stage through pressing.

Cost and efficiency are other major considerations.

For suppliers, pressing complex-shaped preforms in volume offers higher material utilization than sintering simple carbide blanks and machining them later. This leads to lower overall production costs.

For customers, especially those without powder pressing capability but with sintering furnaces and precision grinding equipment, purchasing carbide preforms is often the most efficient supply chain choice. It eliminates the need for powder mixing, granulation, and pressing, while keeping the final manufacturing steps in-house.

Performance control is also a key factor.

Sintering is the stage where cemented carbide achieves its final properties, such as hardness, toughness, and density. By sourcing preforms, customers retain control over sintering parameters, including temperature, time, and atmosphere. This allows fine adjustment of material performance to meet specific application requirements.

Finally, carbide preforms help reduce processing-induced damage.

For certain high-performance carbide grades, grinding or EDM after sintering may introduce micro-cracks or heat-affected zones, which can compromise fatigue strength. Using near-net shape carbide preforms minimizes post-sinter machining, helping preserve the inherent properties of the material.

Main Applications of Carbide Preforms

Carbide preforms are mainly used in applications where complex geometry, wear resistance, and dimensional control are required. Below are the most common application areas in practice.

Complex Wear Parts

Many wear parts feature intricate structures that are difficult to machine after sintering. Typical examples include sealing rings with multiple grooves, steps, and internal or external tapers. Nozzles with special internal flow channels or irregular outlets are also well-suited for tungsten carbide preforms.

In addition, pump rotor and stator assemblies, as well as certain specialized valve components, are often produced using near-net shape carbide preforms to reduce post-sinter machining.

Special Tools and Non-Standard Cutting Components

Some non-standard drills or milling cutters require complex internal cooling channels or special geometries. These components are often first produced as preforms using powder metallurgy methods, including additive manufacturing, and then sintered.

Certain form tools and combination tools also rely on carbide preforms for their complex tool bodies.

Dies and Punches

Carbide preforms are widely used in tooling applications such as powder metallurgy dies and precision stamping die inserts. This is especially true for parts with fine protrusions, recesses, or detailed features that are difficult to achieve through machining alone.

Rods and Tubes

For special specifications, such as extra-long carbide rods or rods with non-standard cross-sections, manufacturers often start with pressed green rods. These are essentially tungsten carbide preforms that are later sintered to achieve the final properties. The same approach applies to certain carbide tubes.

Conclusion

Tungsten carbide preforms are essentially near-net shape carbide products based on the powder metallurgy technology. They are the result of specialization within the carbide industry and a practical solution to complex shape production. What should we do when a carbide part is too complex to be machined economically after sintering? The answer is straightforward. Form the shape while the material is still soft.